Products

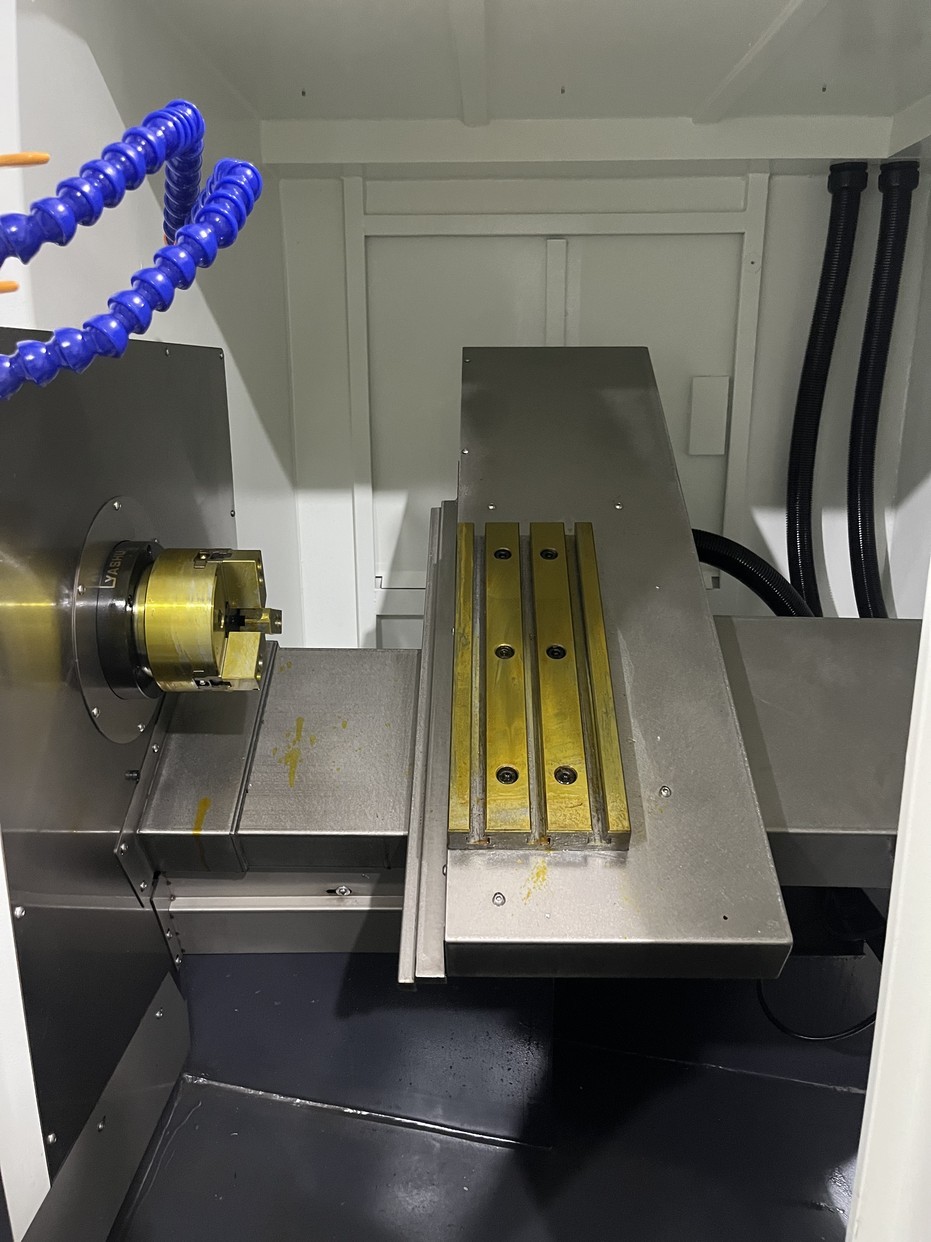

Full-process Machining Of Turning and Milling Compound Machine Tools With Turning Milling Drilling and Tapping Processing Technology

Processing range of turning-milling machine SZGH-46Y: Spindle maximum through hole diameter:45; X-axis maximum travel:1000mm; Z-axis maximum travel:400mm; Y axis mode:Side 4 + end 4 power head; Y axis travel:210mm; Maximum speed of power head:3000 rpm (idling); Milling axis distance:55; Maximum drilling:Medium carbon steel 12/copper aluminum 14; Maximum drill diameter:Drill bit range (2-16);

Classification:

Product Description

SZGH-46Y turning-milling compound machine tool is a high-end CNC machining equipment that integrates the functions of lathes and milling machines. They can complete multiple machining processes in one clamping. Which is commonly used in parts processing in industries such as aerospace, automobile manufacturing, medical equipment, mold manufacturing, and energy equipment.

Core functions and advantages:

1. Process integration and efficiency improvement: It can realize multiple processing technologies such as turning, milling, drilling, tapping, boring, etc. at the same time, reduce the number of multiple clamping of workpieces, shorten the production cycle, and is especially suitable for efficient processing of complex parts.

2. Accuracy guarantee: Avoid positioning errors caused by multiple clamping, complete multiple processes through one processing, and ensure the position accuracy of each processing surface of the parts.

3. Cost optimization: Reduce equipment investment (no need to purchase lathes and milling machines separately) and workshop floor space, reduce labor costs and management difficulty.

Mechanical Specifications

| project | data | project | data |

| Lathe bed form | 30 degree inclined bed (inclined rail) | Tool form | Row of knives |

| Guide rail form | Linear slide | Tool capacity | 8 work stations |

| Spindle maximum speed | 3500r/min | Square knife specifications | 16 mm |

| Spindle nose form | A2-5 | Drilling tool holder | ER20A long pole |

| Material clamping method | Flexible chuck | The distance from the chuck to the sheet metal surface on the left | 930 |

| Maximum bar diameter | Φ45 | Height from ground to spindle center | 1230 mm |

| Spindle through hole diameter | Φ45 | Height from tool table to spindle center | 50 mm |

| Maximum rotation diameter of the bed | Φ420 | Spindle motor | 5.5KW |

| X/Z axis maximum travel | X axis 1000 (diameter) Z axis 400 | X/Z axis servo motor+drive | 1.5KW/6N |

| X/Z axis rapid traverse speed | 20m/min | Total machine power | About 12.0KW |

| Y axis mode | Side 4 + End 4 | Power head speed | 2500rmp |

| Y axis travel | 210mm | Power head clamping type | ER25 |

| A-axis motor | 2.6KW/10N | Servo turret | HS63 (eight stations) Usta |

| Maximum clamping diameter | Φ200 | Machine size (length × width × height) | 2120×1620×1920 |

| Maximum processing length | 300 | Machine weight (approximate weight) | 3000kg |

| Model configuration | |||

| Product name | Origin/Specification | Product name | Origin/Specification |

| CNC system | SZGH | X/Z axis servo motor+drive | SZGH |

| 32 precision ball screw | SZGH | Spindle motor | servo motor |

| 30 precision linear slide rail | SZGH | Hydraulic rotary cylinder | Domestic high quality |

| Tube type precision spindle set | SZGH | cool down | 250W |

| Machinery category | name | Specification | |

| Processing range | Spindle maximum through hole diameter | ⊘45 | |

| X-axis maximum travel | 1000mm | ||

| Z-axis maximum travel | 400mm | ||

| Y axis mode | Side 4 + end 4 power head | ||

| Y axis travel | 210mm | ||

| Power head motor power | 130 motor-2.6KW | ||

| Side drill ER chuck nut end to spindle center | 360 | ||

| Side drilling ER chuck center to chuck seat end face | 260 | ||

| End drill ER chuck center to spindle center | 470 | ||

| End drill RE chuck nut end face to chuck seat end face | 150 | ||

| Power head size | RE25 | ||

| Maximum speed of power head | 3000 rpm (idling) | ||

| Milling axis distance | 55 | ||

| Maximum drilling | Medium carbon steel 12/copper aluminum 14 | ||

| Maximum tapping | Medium carbon steel 12/copper aluminum 14 | ||

| Maximum drill diameter | Drill bit range (2-16) | ||

Optional configuration:

Flying cutter disc,Hydraulic chuck,8 Station Servo turret,Chip conveyor,etc(Support to customize solutions and configurations according to processed parts)

When you receive our CNC machines, you will get following service:

1)We have four areas: production area, assembly area, testing area, and finished product area. The machines will be strictly tested and the inspection reports will be sent to customers before they are shipped;

2)The entire machine including the system is of our own brand, and our hardware and software are all independently developed. Upgrading, learning and operation are simple, and the service is fast;

3)We will give you training video and give details information to help you operate step by step;

4)We will build a after-service group in what-app or by-email , and solve your any question or problem ;

5)All of product information such as : display, user manual , software are in English.It is very convenient for your application;

6)24-months warranty time;

7) Free replacement of accessories during the guarantee period if not man-made damage;

8)Online one to one service, so please don’t worry anything. Specially we export to lots of Countries with lots of quantities machines,have rich export experience;

9)Per your demand , we also can arrange local service to you.

Previous Page

Previous Page

CH

CH

INQUIRY

INQUIRY