Products

Chian High Quality Factory Price Vertical Machining Center 3/4 Axis CNC Milling Drilling Tapping Function Machine

X/Y/Z axis effective travel:500*800*300MM; Spindle Motor Power:7.5KW(Option 6000rpm/24000rpm); Max. drilling diameter:30MM; Max. Tapping Diameter:M16/M20、Aluminum M10 Steel M6; Magazine capacity:10/12 magazines ;

Classification:

Product Description

The milling machine center is a high-precision, high-efficiency automated machine tool that integrates multiple functions such as milling, boring, drilling, and tapping. It is mainly used for precision machining of complex parts.Its core functions include: high-precision machining, complex surface machining, multi-process integration, and automated production.

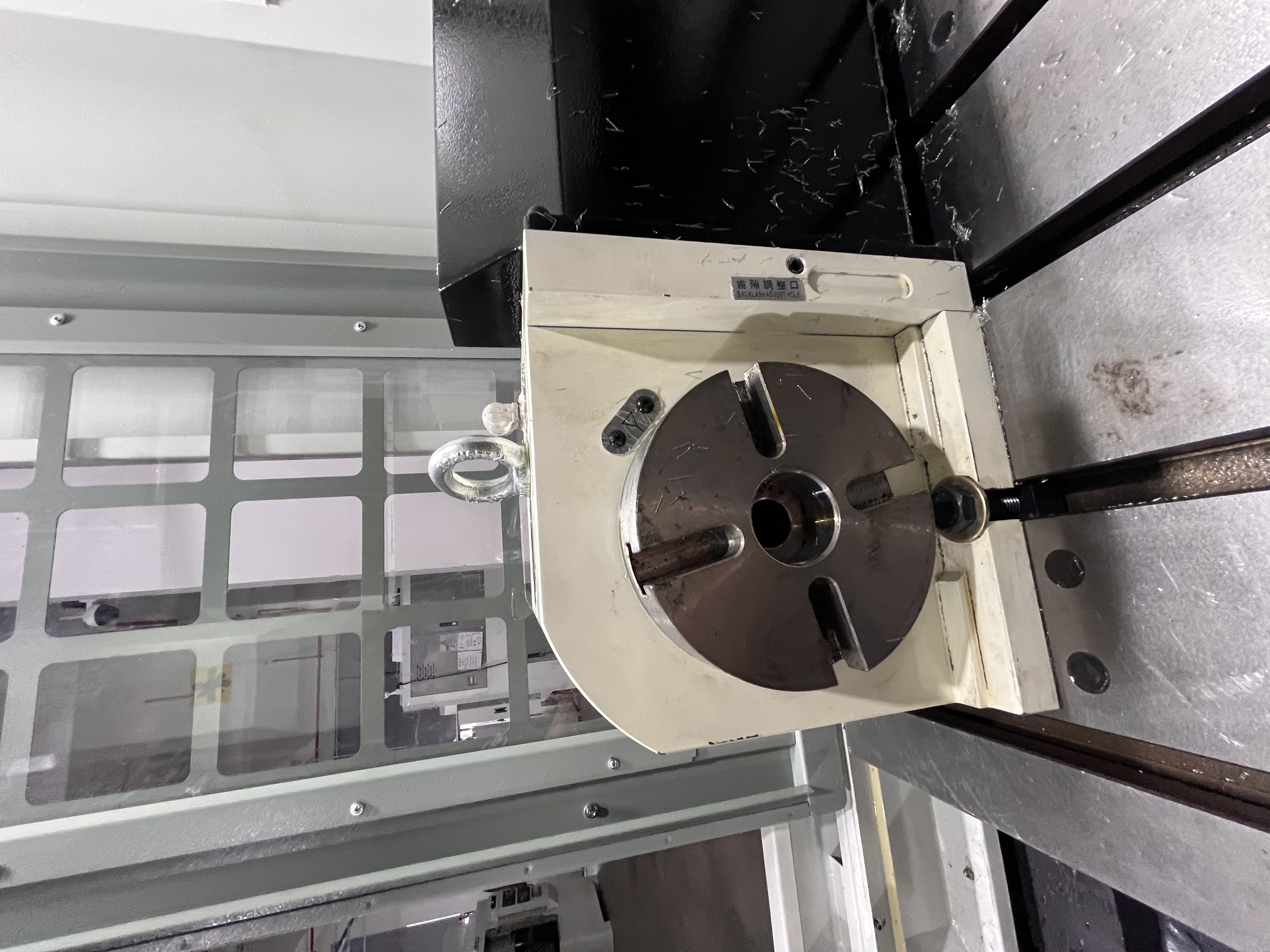

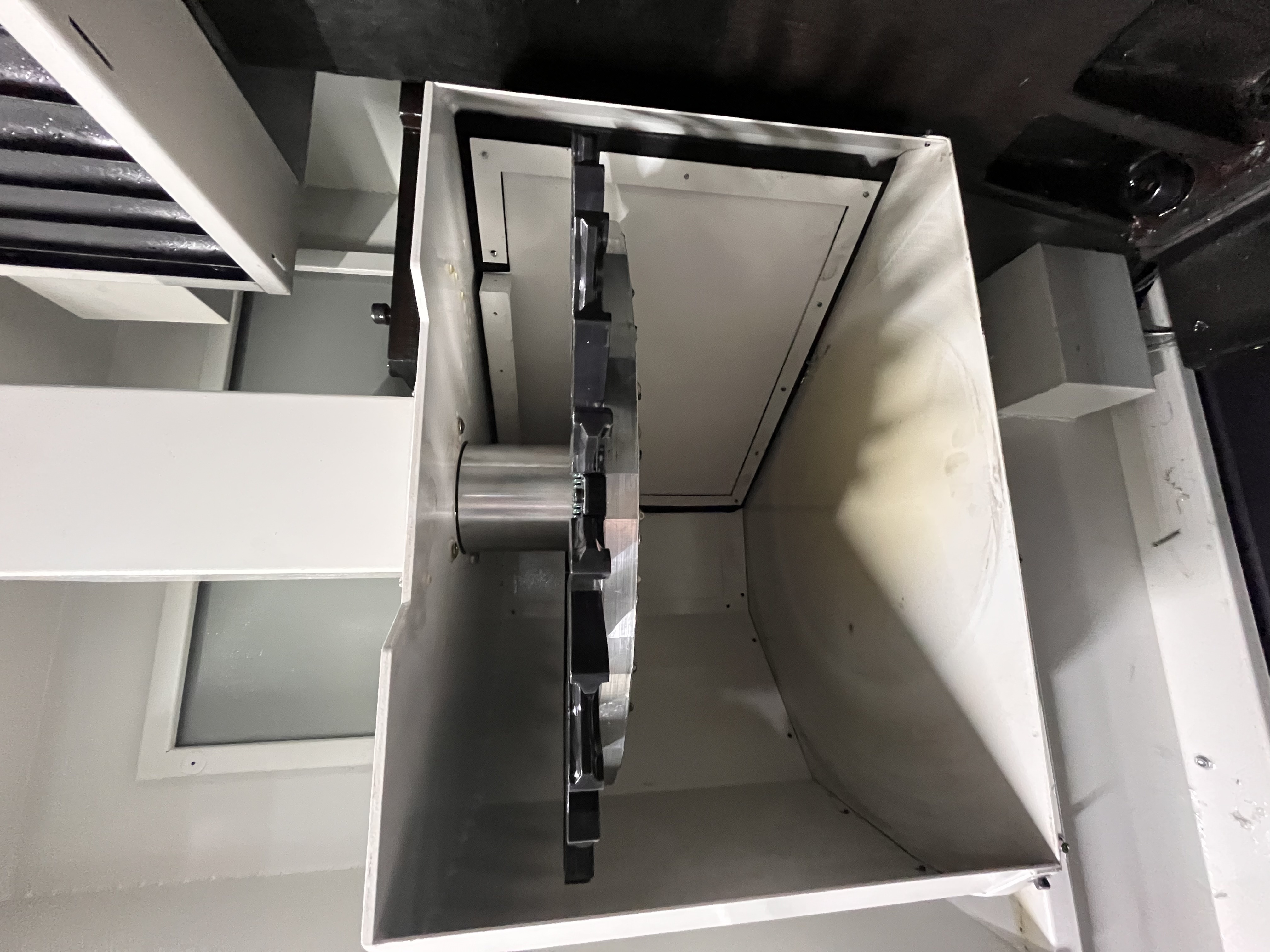

Our milling machine tool SZGH-850 can be equipped with an optional four-axis rotary table to achieve the function of completing multi-faceted three-dimensional machining in one clamping. It is widely used in mold manufacturing and other occasions that require multi-faceted drilling, tapping, or three-dimensional engraving.

Product Advantage

1.The whole lathe machine including the turning system is of independent brand, and the hardware and software are all independently developed, which makes upgrading, learning and operation simple and the service fast;

2.Using Anti-deformation patented heavy-duty base, it is heavy enough to support fast the high-speed and stable movement of the driving head.

3.Using Anti-deformation patented heavy-duty base, it is heavy enough to support fast the high-speed and stable movement of the driving head.

4.The weight is enough to support the anti-vibration and improve the accuracy and smoothness during bar machining.

5.The key components adopt high-quality wear-resistant configurations such as Taiwan, and the spindle installation is all

dynamically balanced.

6.Adopting SZGH electric control package to make electromechanical cooperation play the efficiency.

The common processing methods of SZGH-850 milling machine processing center are as follows:

1. Milling

Plane milling: processing the plane and step surface of parts, such as the base of the box body and the plane of the flange.

Contour milling: milling along the contour trajectory of the part, suitable for parts with complex contours such as cams and gearbox housings.

Cavity milling: processing grooves and cavities (such as mold cavities), requires the use of end mills, cavity milling cutters and other tools.

2. Drilling

Drilling, reaming, and reaming: used to process the positioning holes and assembly holes of parts. When the precision requirements are high, the depth must be accurately controlled with a drill sleeve or a CNC system.

Tapping: processing internal threads through taps, suitable for connecting threaded holes of parts.

Technical Parameter

| Project | Unit | Standard value | Max value | |

| Processing capacity | Max. drilling diameter | mm | Ф30 | - |

| Max. Tapping Diameter | mm | M16/M20、Aluminum M10 Steel M6 | - | |

| Max. milling cutter diameter | mm | Ф63 | Ф50 | |

| Max Spindle speed | rpm | 6000 | Optional 24,000-rpm motorized spindle | |

| Handle Type | - | BT40 | BT30 | |

| Magazine capacity | - | 10 magazines | 12 magazines | |

| Repeatability | mm | 0.01 | 0.01 | |

| Workbench | Distance from table surface to spindle end | mm | Minimum 150 Maximum 300 | Minimum 150 Maximum 300 |

| Effective stroke of working surface | mm | 800*500 | 800*500 | |

| Travels | X-axis effective travel | mm | 500 | 500 |

| Y-axis effective travel | mm | 800 | 800 | |

| Z-axis effective travel | mm | 300 | 300 | |

| Feed | X-axis rapid traverse | m/min | 30 | 30 |

| Y-axis rapid traverse | m/min | 30 | 30 | |

| Z-axis rapid traverse | m/min | 25 | 25 | |

| Various cutting suggested speeds | m/min | 10000 | 10000 | |

| Spindle | Max.Spindle Speed | rpm | 6000 | 24000 |

| Spindle Motor Power | kw | 5.5kw/7.5kw | 7.5kw | |

| Spindle type | - | Mechanical spindle | Optional electric spindle | |

| Spindle taper | - | BT40 | BT30 | |

| Dimensions | Dimensions | mm | 2200 x 1850x 2550 | 2200 x 1850x 2550 |

| Total Weight | kg | 3500 | 3500 | |

| Machine tool specifications and component items | Specification | Standard | ||

| Part Specifications | Screw | 32mm | Taiwan precision p grade | |

| Guide rail | 30mm | Taiwan Precision C3 Grade | ||

| Bearing | - | SZGH | ||

| Spindle | BT30 | SZGH | ||

| CNC Control | - | SZGH | ||

| Feed servo | - | SZGH | ||

| Spindle servo motor | 7.5kW | SZGH | ||

| Machine specifications | Tool magazine | 12 handle | SZGH | |

| Base form | - | Heavy-duty anti-deformation patented base | ||

When you receive our CNC machines, you will get following service:

1)We have four areas: production area, assembly area, testing area, and finished product area. The machines will be strictly tested and the inspection reports will be sent to customers before they are shipped;

2)The entire machine including the system is of our own brand, and our hardware and software are all independently developed. Upgrading, learning and operation are simple, and the service is fast;

3)We will give you training video and give details information to help you operate step by step;

4)We will build a after-service group in what-app or by-email , and solve your any question or problem ;

5)All of product information such as : display, user manual , software are in English.It is very convenient for your application;

6)24-months warranty time;

7) Free replacement of accessories during the guarantee period if not man-made damage;

8)Online one to one service, so please don’t worry anything. Specially we export to lots of Countries with lots of quantities machines,have rich export experience;

9)Per your demand , we also can arrange local service to you.

CH

CH

INQUIRY

INQUIRY