PRODUCTS

SZGH can provide lathe controller, milling machine controller, engraving controller, grinder controller, etc.

Spindle Servo Motors And Drivers

High-performance control functions are comprehensive: stable speed control, precise position control, and excellent torque control.

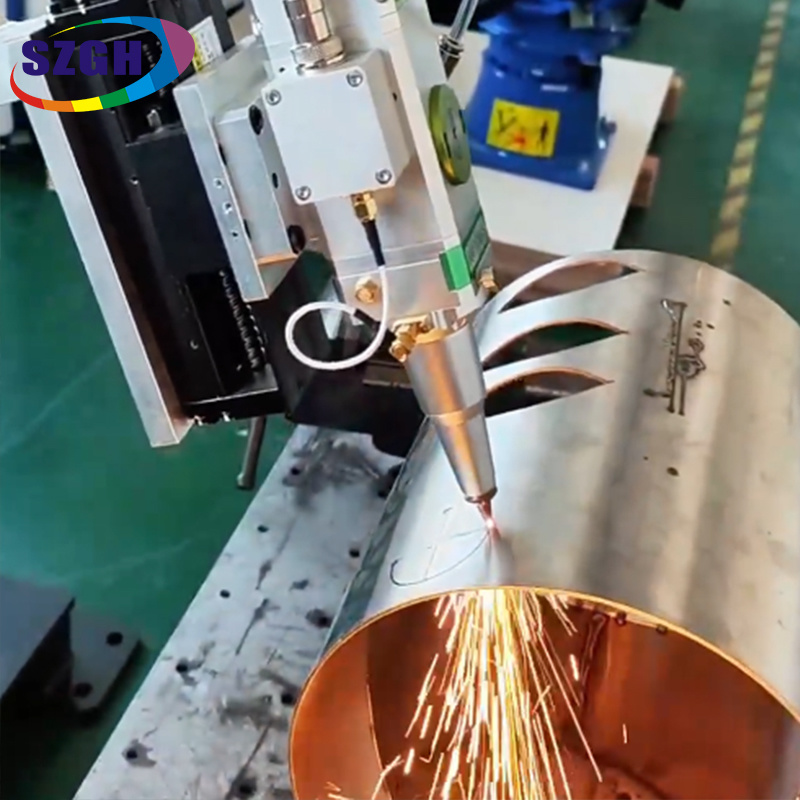

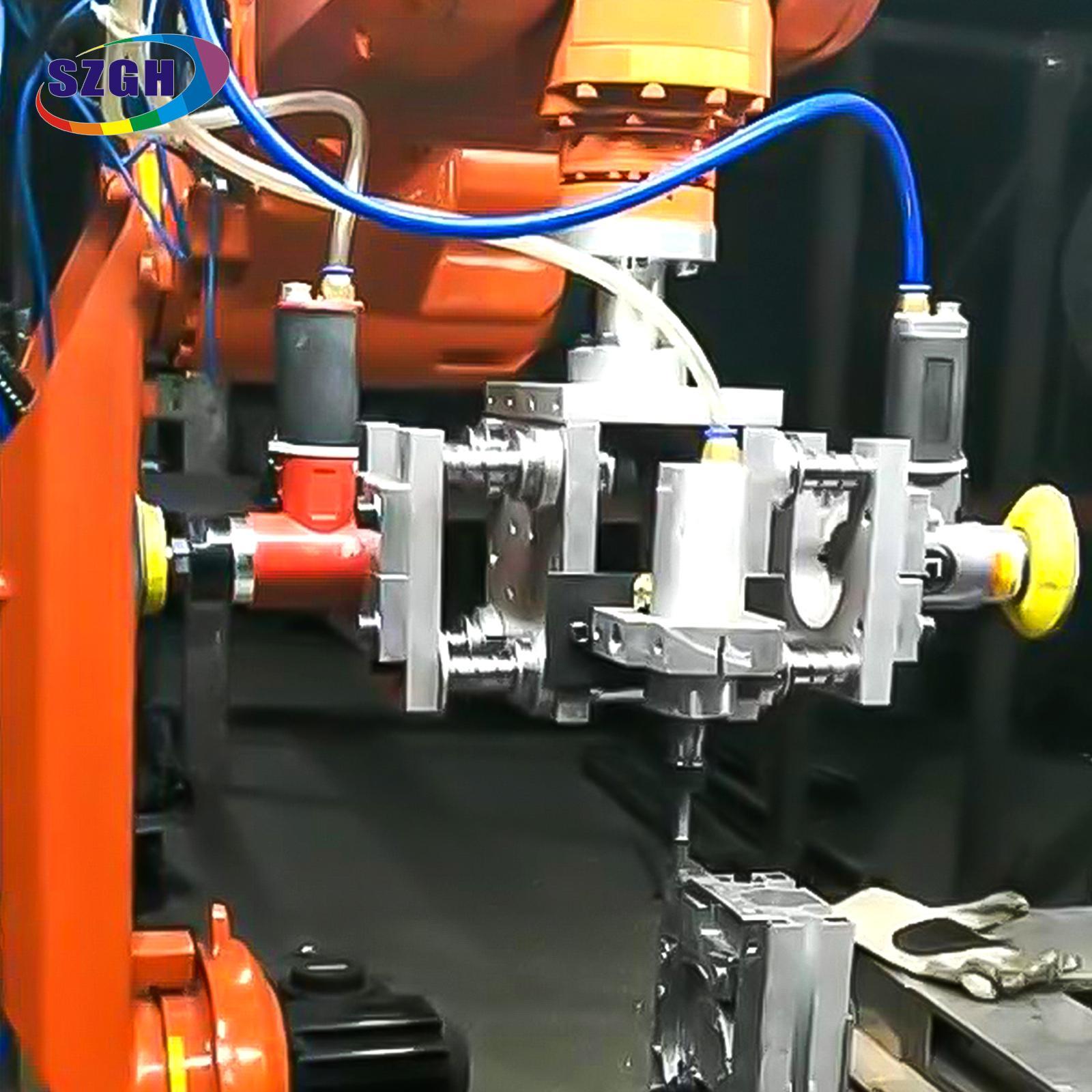

Robot Application Cases

APPLICATION

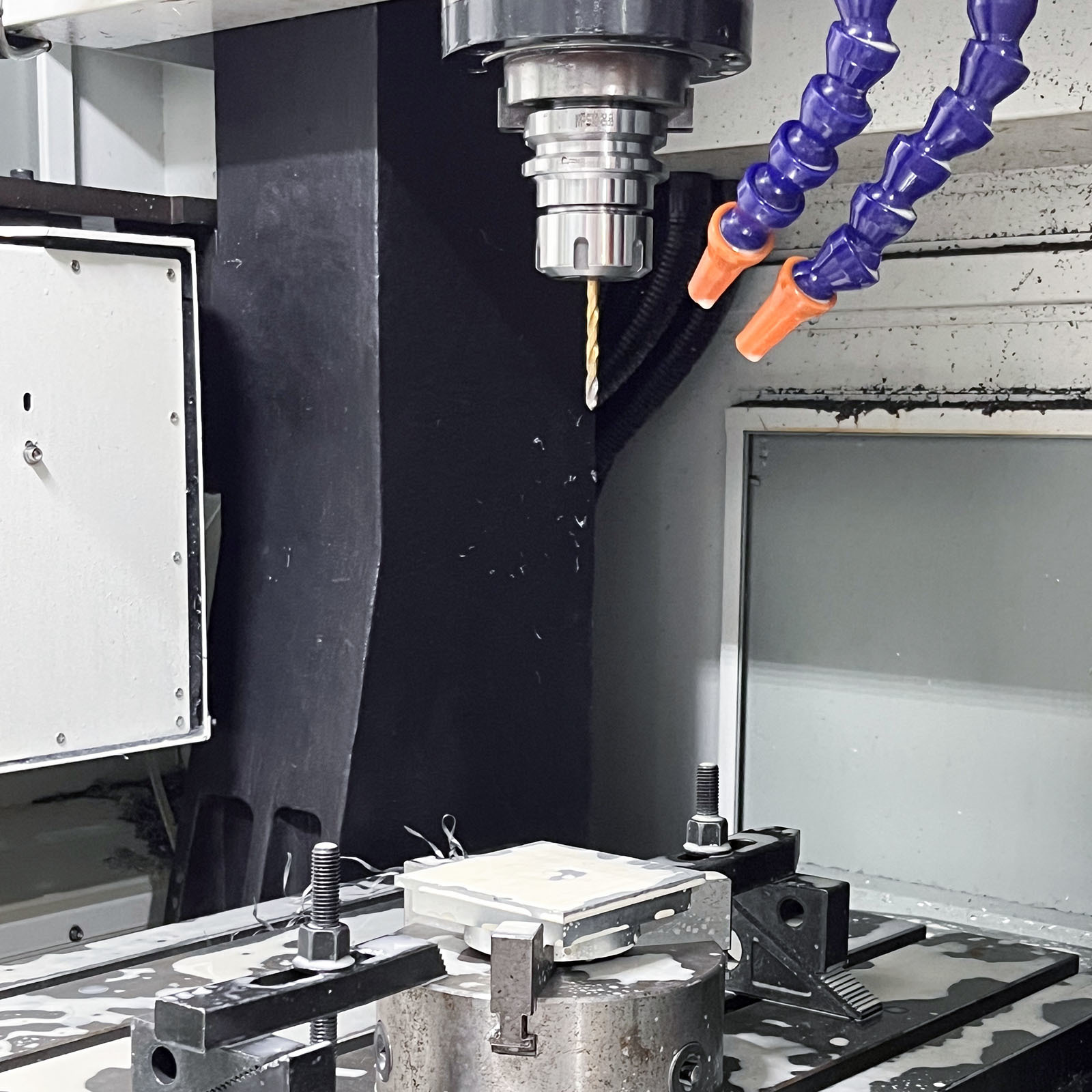

Machine Tool Application Case

APPLICATION

About Us

Shenzhen Guanhong Automation Co., Ltd.

Shenzhen Guanhong Automation Co., Ltd. (formerly known as "Shenzhen Guanhong Automation Technology Co., Ltd. (established on November 19, 2010) specializes in design projects, marketing and overseas trade. Our focus is to provide quality welding robots, palletizing robots, loading and unloading robots, spraying robots, grinding robots, lathe numerical control systems, milling numerical control systems, numerical control engraving systems, AC servo motors and drivers, etc...

Enterprise establishment

Existing Employees

Global Customer Service

NEWS

Inquiry Message

INQUIRY

CH

CH

INQUIRY

INQUIRY