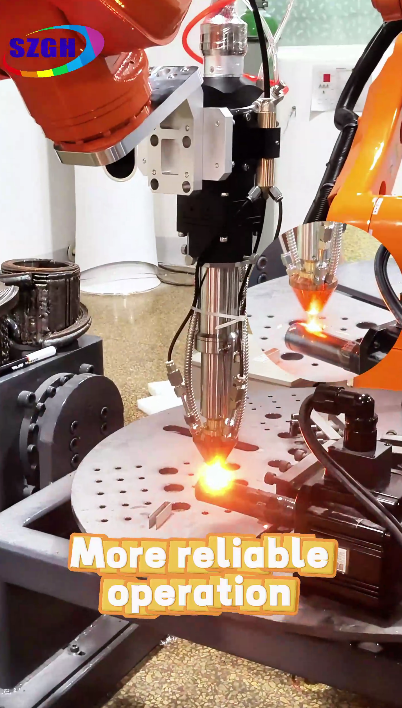

SZGH Robot Application Case Update-Embrace the future of welding with SZGH Robotic Laser Cladding!

Embrace the future of welding with SZGH Robotic Laser Cladding! 6 axis general-purpose robot SZGH-T1850-10C:payload 10KG,arm reach 1850mm; Application:laser welding Installation:Floor mounted Environmental performance:IP65

Why Laser Welding is the Optimal Solution for Stainless Steel?

Today we continue to explore the advantages of laser welding stainless steel. We all know that stainless steel is a widely used material, which is used in the automotive industry, kitchen and bathroom, home appliances, industrial facilities and other industries. In the processing and application, welding is often required to achieve the connection between workpieces. In this processing process, welding stainless steel with a laser welding machine is the choice!!

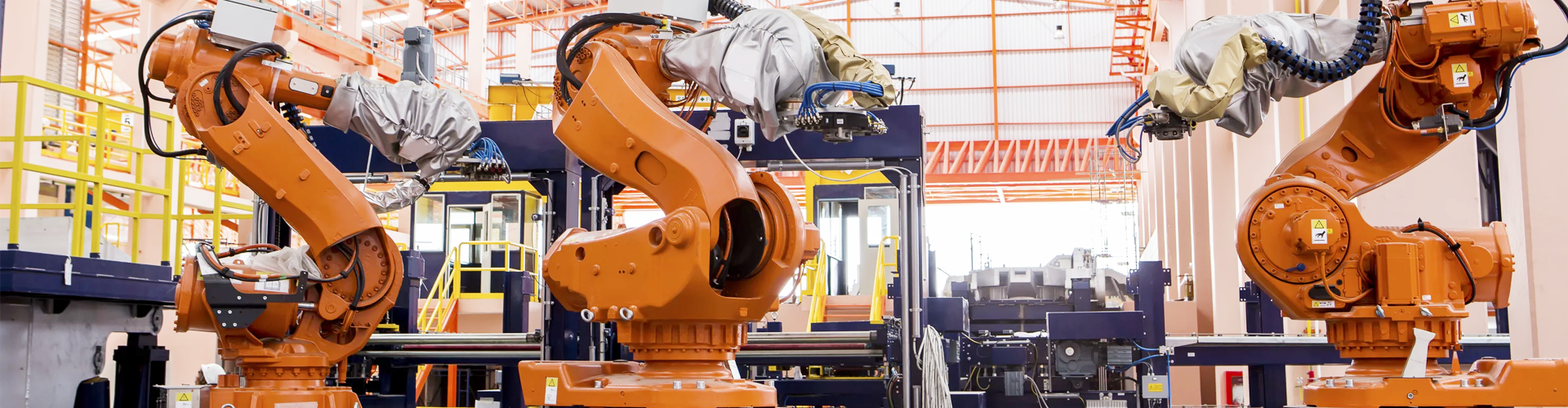

SZGH Handling Robot Stamping Loading And Unloading Extrusion Molding 4 Axis Robot

Automation Solution: The SZGH 4-axis robot is equipped with a fixture to accurately clamp the workpiece from the workpiece box and put it into the stamping machine for stamping. In addition, double grippers can be customized to complete two stamping processes at the same time, greatly improving efficiency. Our robots occupy a small space and have a repeatable positioning accuracy of ±0.05 mm, which meets the requirements of stamping loading and unloading of various small parts.

How does SZGH welding robot achieve nine-axis linkage?

How does SZGH welding robot achieve nine-axis linkage? The motion space of welding robots can meet the needs of most industries. However, in welding operations, some weldments with complex structures are often encountered. If the position of the weldment is not changed in time, it will interfere with the welding gun, causing the welding gun to be unable to weld along the set path. In order to ensure the welding quality and improve the welding efficiency, it is necessary to change the position of the weldment in time and adjust the weld to the best position for welding.

SZGH robot arm work with 40 T Single arm punching machine

Are you still looking for an automated production solution for your single arm punching machine ? Our robots can completely replace manual labor to complete the automatic stamping production of single punching equipment, greatly improving your production efficiency and production safety, and liberating productivity!! Here are the solutions we provide to our customer's production line: Processed products:0.8mm Thick board SZGH provide the solution 1. 8 set SZGH-T1500-C-6 10kg ,6 axis , 1500mm reaching robot arm 2. 8 set Fixture

Lathe machine processing "working with" robots

The case in the video is to install a double-head fixture on our general-purpose SZGH-T series robot, clamp the cutting workpiece and load it into the lathe machine collet to complete the processing. It is more accurate, fast and safer than manually placing materials. For the processing of small and medium-sized parts with large production batches and short processing time, or bulky workpieces that need to be hoisted, the integration of robots and cnc machines is more advantageous.

What is a welding robot? What are its characteristics?

The characteristics of SZGH welding robots are as follows: 1. Improve welding efficiency. 2. Stabilize welding quality. 3. Help enterprises arrange production. 4. Help enterprises relieve the pressure of recruiting workers.

The SZGH collaborative robot has a repeatability positioning accuracy of up to ±0.02 mm. In precision machining, it can ensure the consistency of multiple robots operating simultaneously, realize standardized production of products, improve production quality, and achieve a yield rate of more than 99%. The maximum cycle speed of 4 m/s can efficiently transport parts and improve production efficiency by 20% - 40% during loading and unloading of machine tools

CH

CH

INQUIRY

INQUIRY