Turning Machining Explained: Characteristics, Methods, and CNC Lathe Selection Guide

What is Turning Machining-Main Characteristics of Turning Machining-Representative Turning Machining Methods-Core Requirements for CNC Turning Machine Performance-Key Selection Points for CNC Lathes

SZGH-650 CNC Milling Machine Application Case for Steel Plate End Milling Drilling Tapping

Steel plate components are widely used in machinery, automated structural parts, tooling fixtures, and mounting substrates, demanding high precision in flatness, hole alignment, and thread quality. The SZGH-650 Vertical CNC Milling Machine, featuring a stable structural design and proven machining processes, efficiently performs multiple operations on steel plate parts—including end-face milling, drilling, and tapping—meeting customers' dual requirements for both productivity and quality.

Small precision 2-axis lathe turning machine SZGH-36J: ideal for efficient processing of short bars

Small precision 2-axis lathe machine SZGH-36J: Max. diameter of bar bore 35mm; Max. length of workpiece 230mm; X-axis effective travel 600mm; Z-axis effective travel 230mm; Machining accuracy of the workpiece ±0.01mm; Option:flying cutter disc;

Standard configuration: X/Z axis effective travel:1000*400mm; 2 axis cnc lathe system; 5.5KW spindle; Optional configuration: hydraulic chuck + 8-station turret Advantages: 1. Large clamping force, stable clamping, high degree of automation; 2. Fast tool change, accurate positioning, strong tool compatibility; 3. Suitable for parts processing that requires multi-process integration, high precision, and high efficiency;

SZGH auto cnc lathe machine SZGH-36J automatic feeding turning and parts loading application

As a key equipment in the field of mechanical processing, the lathe machine's degree of automation and processing accuracy have a vital impact on production efficiency and product quality. The lathe's automatic feeding system and hydraulic chuck are important devices to improve lathe performance. Our lathe SZGH-36J with option automatic feeder and the hydraulic chuck can acheive automatically feed and save your processing time; it realizes automatic feeding and loading.

Elevate Your Machining Efficiency With Turning-milling Compound Machine T oolSZGH-46Y

We are pleased to introduce the SZGH-46Y turning-milling compound machine tool — designed to lead a new era of intelligent machining. Featuring the advanced SZGH-1080TC lathe system, it delivers precise calculations and rapid response times. Paired with a hydraulic chuck, it ensures quick, stable clamping, enhancing both efficiency and workpiece quality. Its 4+4 power head and 8-station servo turret support multi-tool operations simultaneously, allowing multiple processes in a single setup — significantly reducing tool change and clamping time, especially for complex parts.

Enhance Your Production Efficiency with SZGH CNC Lathe Solutions

At SZGH, we are excited to introduce our fully automated feeding and receiving solutions designed to revolutionize your parts processing production line. By integrating a 2-axis lathe (SZGH-36J) with a conveyor belt and receiver, your operation can achieve unprecedented efficiency—requiring only periodic product pickups every two to three hours.

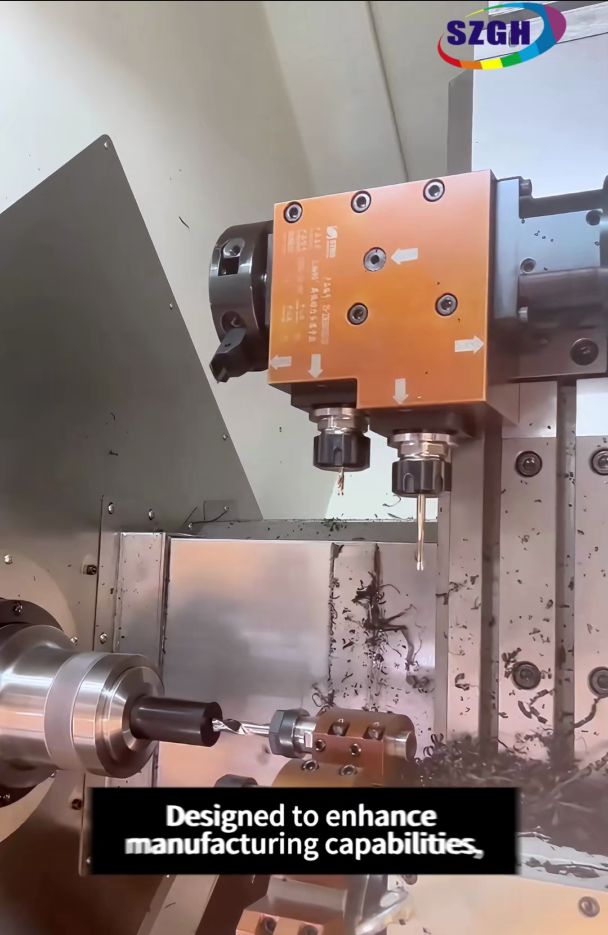

Introduction of Lathe Machine with Enhanced Capabilities:SZGH-46J

The lathe machine SZGH-46J in the video has added accessories such as a side 2 power head and a servo turret. One set of machine has realized the function of turning and milling, which can be used for workpiece processing such as side drilling, tapping, and slot milling!!!

TK50 lathe suitable for processing products in machinery,automobiles,motorcycles

The TK50 series is a simple CNC lathe machine driven by a servo main motor. It has an independent spindle and can realize infinitely variable speed. Equipped with the SZGH-CNC1000TDb/c system, it realizes two-axis control and can automatically complete the processing of internal and external cylindrical surfaces, arbitrary conical surfaces, arc surfaces, end surfaces, and metric and imperial threads, etc.

Lathe machine processing "working with" robots

The case in the video is to install a double-head fixture on our general-purpose SZGH-T series robot, clamp the cutting workpiece and load it into the lathe machine collet to complete the processing. It is more accurate, fast and safer than manually placing materials. For the processing of small and medium-sized parts with large production batches and short processing time, or bulky workpieces that need to be hoisted, the integration of robots and cnc machines is more advantageous.

What does a CNC lathe machine do? What are the steps for lathe machine to process parts?

The following are some common application areas of our SZGH lathes machines: 1.Parts processing: It can be used to process various parts, such as mechanical parts, automotive parts, aerospace parts, etc. By writing different processing programs, complex shapes of parts can be processed and processing accuracy and efficiency can be improved. 2.Thread processing: It can be used to process various types of threads, such as internal threads, external threads, special threads, etc. By writing thread processing programs, high-precision and high-efficiency thread processing can be achieved. 3.Milling processing: Milling can be performed using special tools and cutting methods. By writing milling processing programs, complex shapes of milling can be achieved, such as grooving, cutting, contour processing, etc. 4.Hole processing: It can be used to process various types of holes, such as diameter holes, blind holes, inclined holes, etc. By writing hole processing programs, high-precision and high-efficiency hole processing can be achieved. 5.Surface processing: It can be used to process various types of surfaces, such as spheres, cylinders, inclined surfaces, etc. By writing surface processing programs, high-precision and high-efficiency surface processing can be achieved.

CH

CH

INQUIRY

INQUIRY