Products

SZGH Milling Machining Center 3 Axis Vertical Drilling Tapping Machine Tool With High Precision Spindle High Speed Feed System

Workbench size (W*L)mm:600*500; Tool magazine capacity:10/12 station tool magazine; Maximum drilling diameter mm:35; Maximum tapping diameter mm:M16/M20; Maximum milling cutter diameter mm:63;

Classification:

Product Description

Product Overview

The model SZGH-650 is an automated cnc milling machine with multiple functions such as milling, boring, drilling and tapping. It is designed to meet the high-precision and high-efficiency processing needs of complex parts.

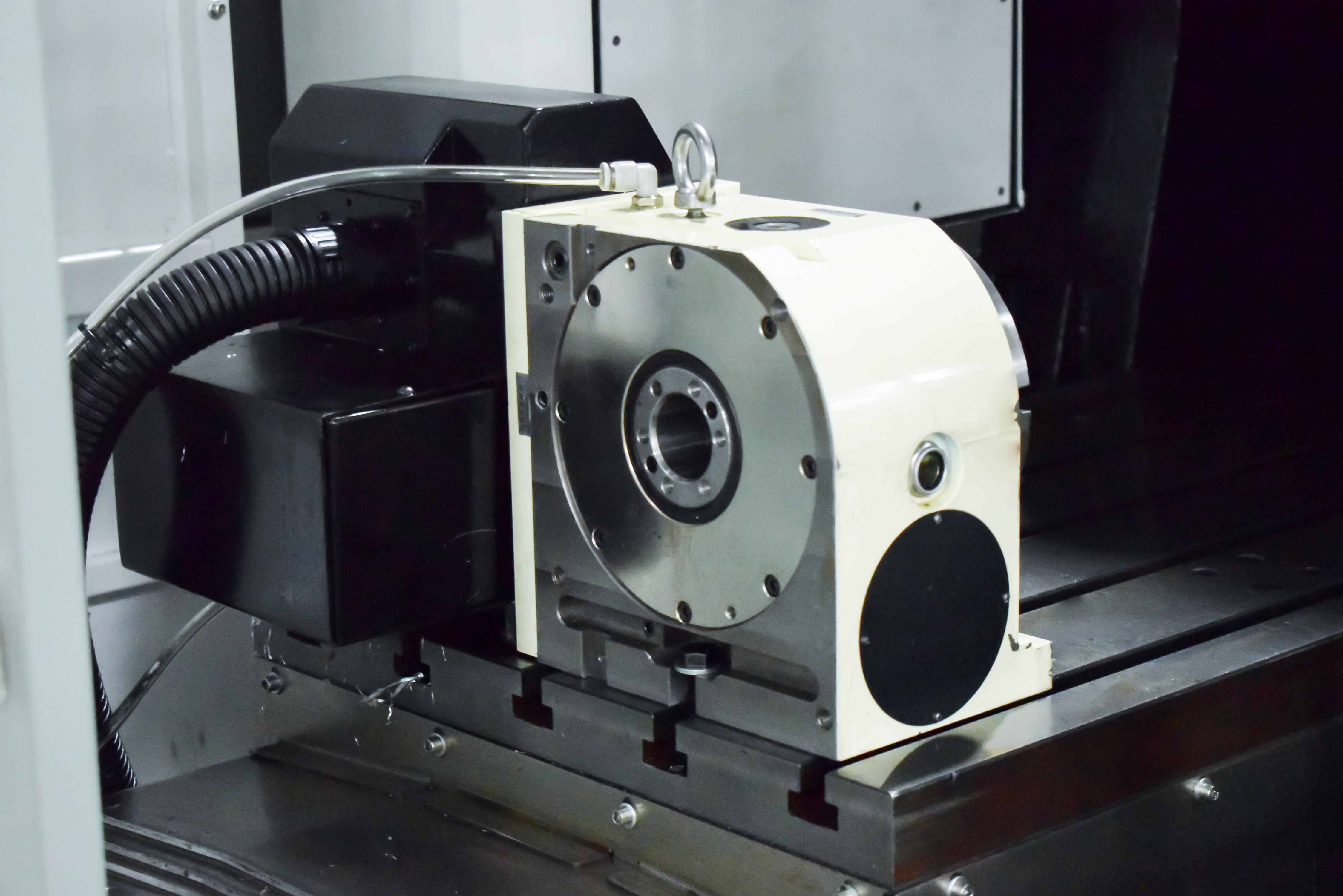

The spindle of this vertical machining center SZGH-650 is perpendicular to the worktable, with a small footprint and compact structure, suitable for processing small and medium-sized parts.The worktable is generally rectangular and can move along the X and Y axes, and the spindle box moves along the Z axis to achieve three-coordinate linkage processing. The fourth axis (rotation axis) can also be optionally equipped to expand the processing capacity and realize the processing of more complex parts.

Product Features

High-precision processing + high-efficiency processing + high reliability and stability

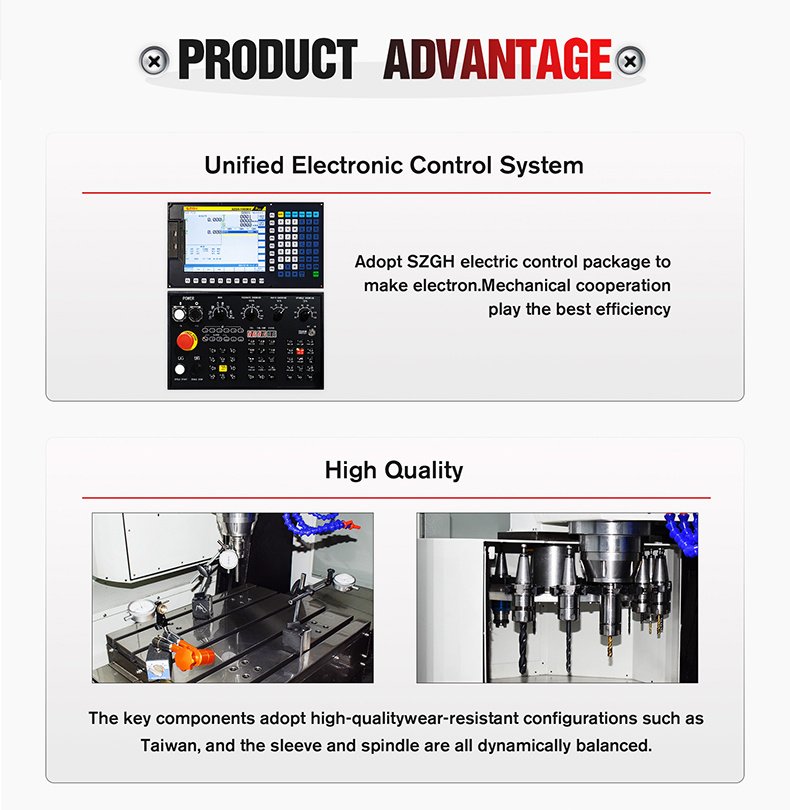

1. Precision mechanical structure: key components are made of high-quality wear-resistant configurations such as Taiwan, and the spindle installation is dynamically balanced. The anti-deformation patented heavy-duty base is used, which is heavy enough to support the high-speed and stable movement of the power head. The weight is sufficient and the shock resistance is good, which improves the accuracy and smoothness of bar processing and provides a solid foundation for precision machining.

2. Advanced CNC system: SZGH electronic control kit is adopted, equipped with the independently developed Modbus milling machine controller SZGH-1080MIC, so that the electromechanical synergy can achieve maximum efficiency. High-precision machining of complex curved surfaces is achieved to meet the strict requirements of aerospace, precision molds and other industries for part accuracy.

3. High-precision spindle: The spindle is supported by high-precision bearings, which are optimized by dynamic balancing and have high rotation accuracy. The spindle taper hole accuracy meets ISO standards to ensure the coaxiality and stability of tool installation. Optional electric spindle, the maximum speed can reach 24000rpm, and the configuration and optimal cutting speed can be selected according to different materials and processing processes to effectively improve the quality of the machining surface.

4. Large-capacity tool magazine: Standard configuration 10 tool magazine, optional 12-station tool magazine. The tool magazine adopts advanced tool changing mechanism, accurate positioning, fast tool changing, can store a variety of tools, meet the tool needs of complex parts multi-process processing, reduce tool preparation time, and improve production efficiency.

Product Parameters

| Details | SZGH-650B (mechanical spindle) | SZGH-650D (variable frequency electric spindle) | |||

| workbench | Workbench size (W*L)mm | 600*500 | 600*500 | ||

| weight capacity | 250 kg | 250 kg | |||

| Spindle | Spindle speed | Maximum speed: 6000 rpm | Maximum speed: 24000 rpm | ||

| Spindle power | 5.5kw | 7.5kw | |||

| Spindle taper hole | BT40 | BT30 | |||

| Distance from work table to spindle end face mm | Minimum 150 Maximum 450 | Minimum 150 Maximum 450 | |||

| Fast-moving | X axis m/min | 30 | 30 | ||

| Y axis m/min | 30 | 30 | |||

| z-axis m/min | 25 | 25 | |||

| Feed | journey | X axis mm | 500 | 500 | |

| Y axis mm | 600 | 600 | |||

| z-axis mm | 300 (the worktable is 150 from the end face of the spindle) | 300 (the worktable is 150 from the end face of the spindle) | |||

| Cutting feed speed m/min | 10000 | 10000 | |||

| Repeat positioning accuracy mm | 0.01 | 0.01 | |||

| ATC | Tool magazine capacity | 10-station servo tool magazine | 12-station servo tool magazine | ||

| Tool holder type | BT40 | BT30 | |||

| Maximum drilling diameter mm | Ф35 | Frequency conversion electric spindle | Servo electric spindle | ||

| Maximum tapping diameter mm | M16/M20 | Tapping is not supported | Aluminum M10 Steel M6 | ||

| Maximum milling cutter diameter mm | Ф63 | Ф50 | |||

| Air pressure kgf/cm2 | 5 | 5 | |||

| Maximum power kW | 10 | 14 | |||

| Machine tool dimensions length*width*height (mm) | 1650*1800*2450 | 1650*1800*2450 | |||

| Machine weight | 2900 kg | 2900 kg | |||

Optional configuration:

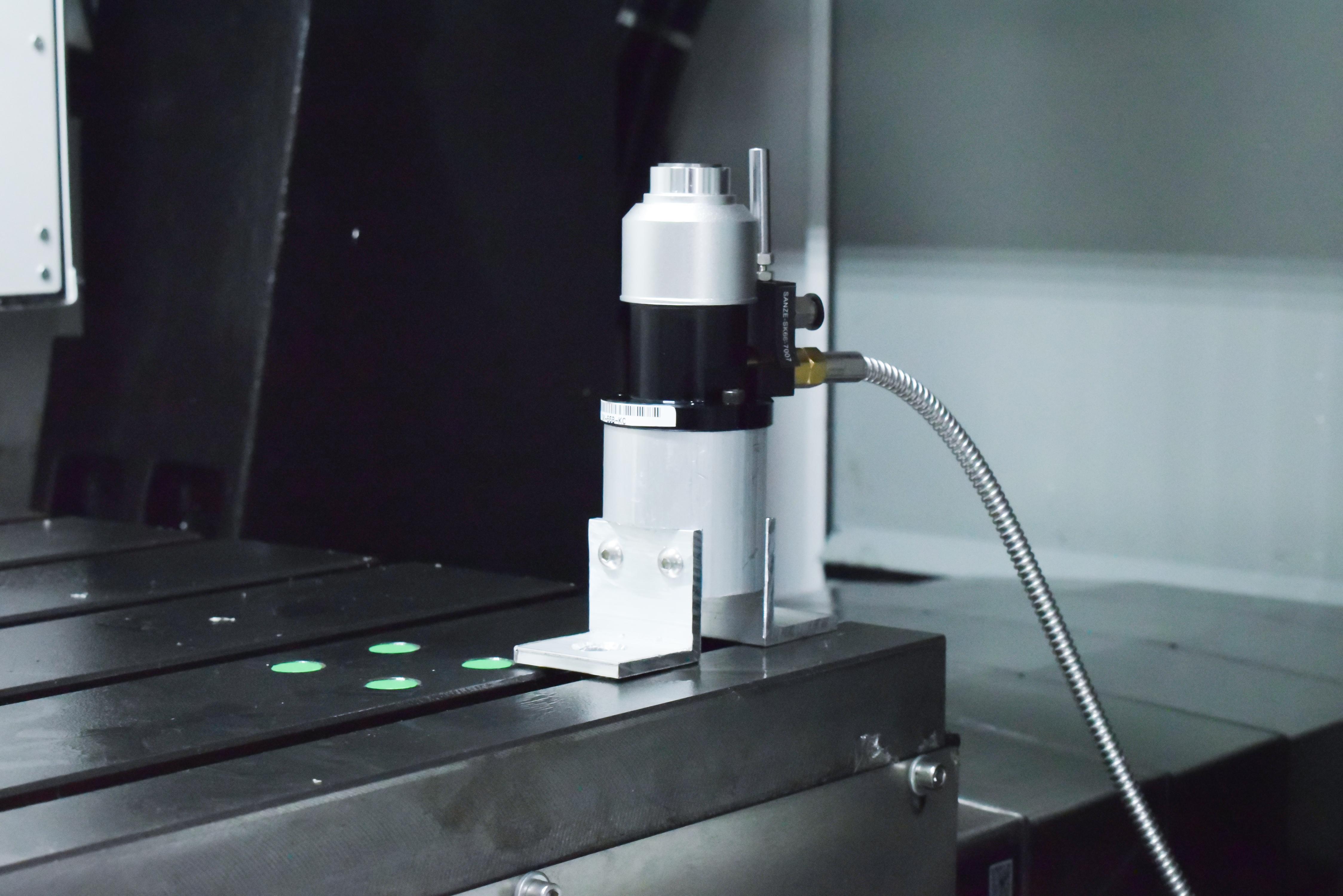

The 4th axis rotary table,tailstock,tool setting probe,probe,etc

When you receive our CNC machines, you will get following service:

1)We have four areas: production area, assembly area, testing area, and finished product area. The machines will be strictly tested and the inspection reports will be sent to customers before they are shipped;

2)The entire machine including the system is of our own brand, and our hardware and software are all independently developed. Upgrading, learning and operation are simple, and the service is fast;

3)We will give you training video and give details information to help you operate step by step;

4)We will build a after-service group in what-app or by-email , and solve your any question or problem ;

5)All of product information such as : display, user manual , software are in English.It is very convenient for your application;

6)24-months warranty time;

7) Free replacement of accessories during the guarantee period if not man-made damage;

8)Online one to one service, so please don’t worry anything. Specially we export to lots of Countries with lots of quantities machines,have rich export experience;

9)Per your demand , we also can arrange local service to you.

Choosing our milling machine processing center is choosing an efficient, accurate and reliable processing solution, which will make your company stand out in the fierce market competition and achieve higher production value and economic benefits. If you are interested in our products or have any questions, please feel free to contact us, we will serve you wholeheartedly!

Previous Page

Previous Page

CH

CH

INQUIRY

INQUIRY