Products

Mechanical Processing Automation Lathes SZGH-46J 2 Axis Lathe Controller System Processing Of Bar Material

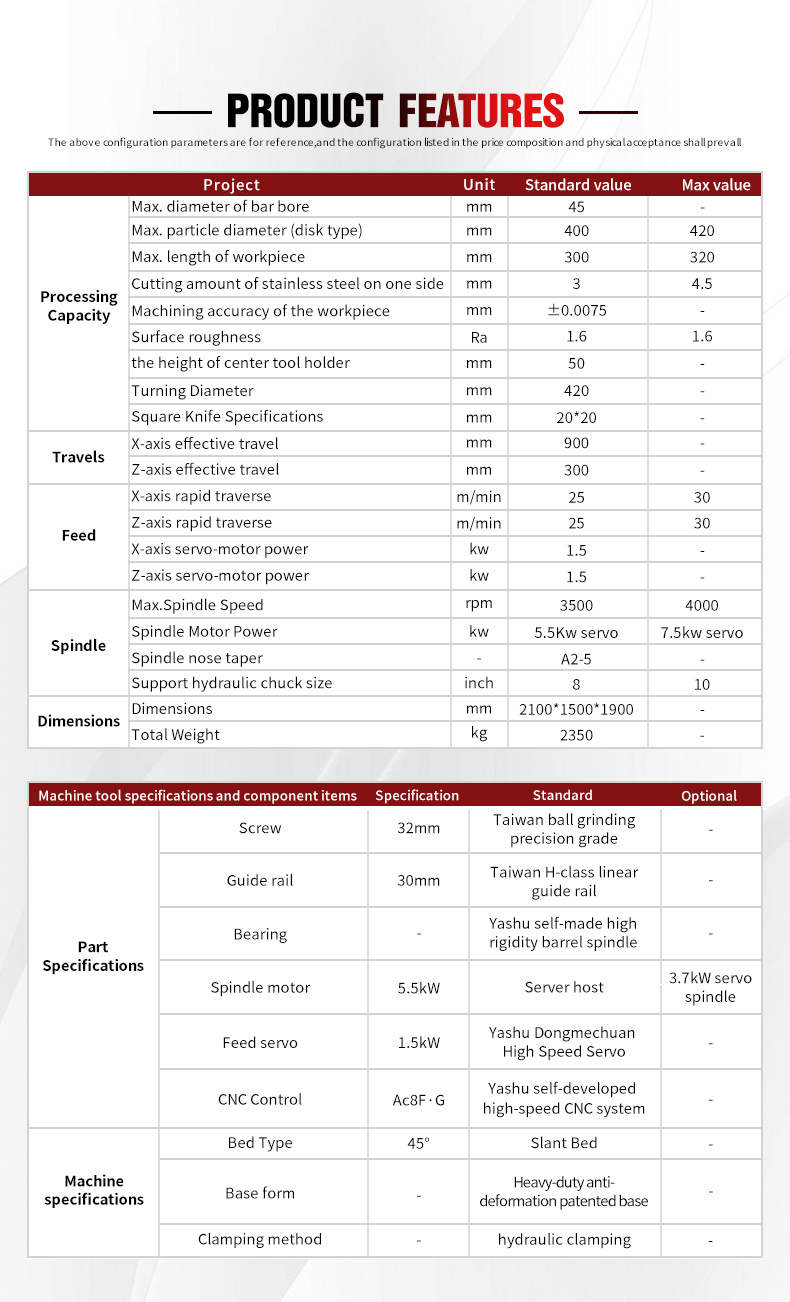

Two-axis CNC Lathe Machinery Auto Turning Machine SZGH-46J: Maximum bar diameter: Φ45; Maximum rotation diameter on the bed: Φ420; X/Z axis maximum travel: X axis 1000mm /Z axis 400mm; Maximum clamping diameter: Φ200 Maximum processing length: 300mm; Guide rail type: linear slide rail;

Classification:

Product Description

As a key equipment in the field of mechanical processing, the degree of automation and processing accuracy of lathes have a vital impact on production efficiency and product quality.The model SZGH-46J match with our new series 2 axis lathe controller system,which is suitable for processing of bar material within 45mm and pellet material within 60mm.Easily process shaft parts, disc parts, and threaded parts. For example, various specifications of bolts can be processed by thread turning to ensure the thread accuracy and surface quality of the bolts.

Product Description

1.It is suitable for batch production of copper, iron, aluminum and stainless steel bars within 45mm, and batch production of open-type forged parts with automatic feeding of pellets within 60mm.

2.It can also be equipped with hydraulic chucks for single-piece production of parts within 350mm. Using multiple patented technologies such as high rigidity and anti-deformation structure, it is suitable for processing products with a single-side cutting amount within 4mm, precision tolerance within ±0.0075mm, and smoothness within 1.6.

3.It is widely used in the processing of large parts with high precision and rigidity. Through careful design and matching, the performance of each accessory can be fully utilized to achieve the cost-effective ratio.

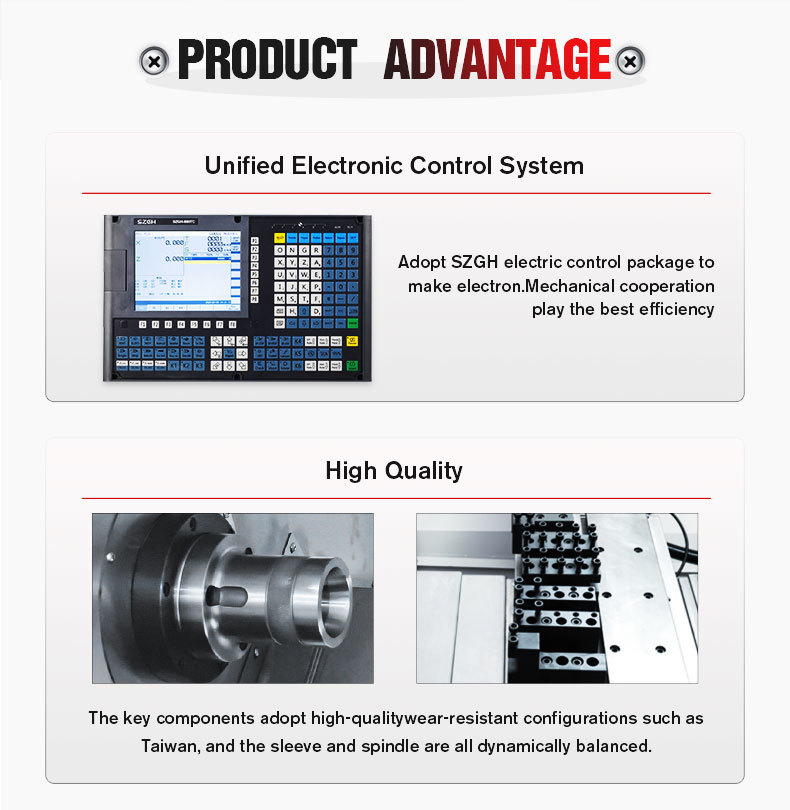

Product Advantage

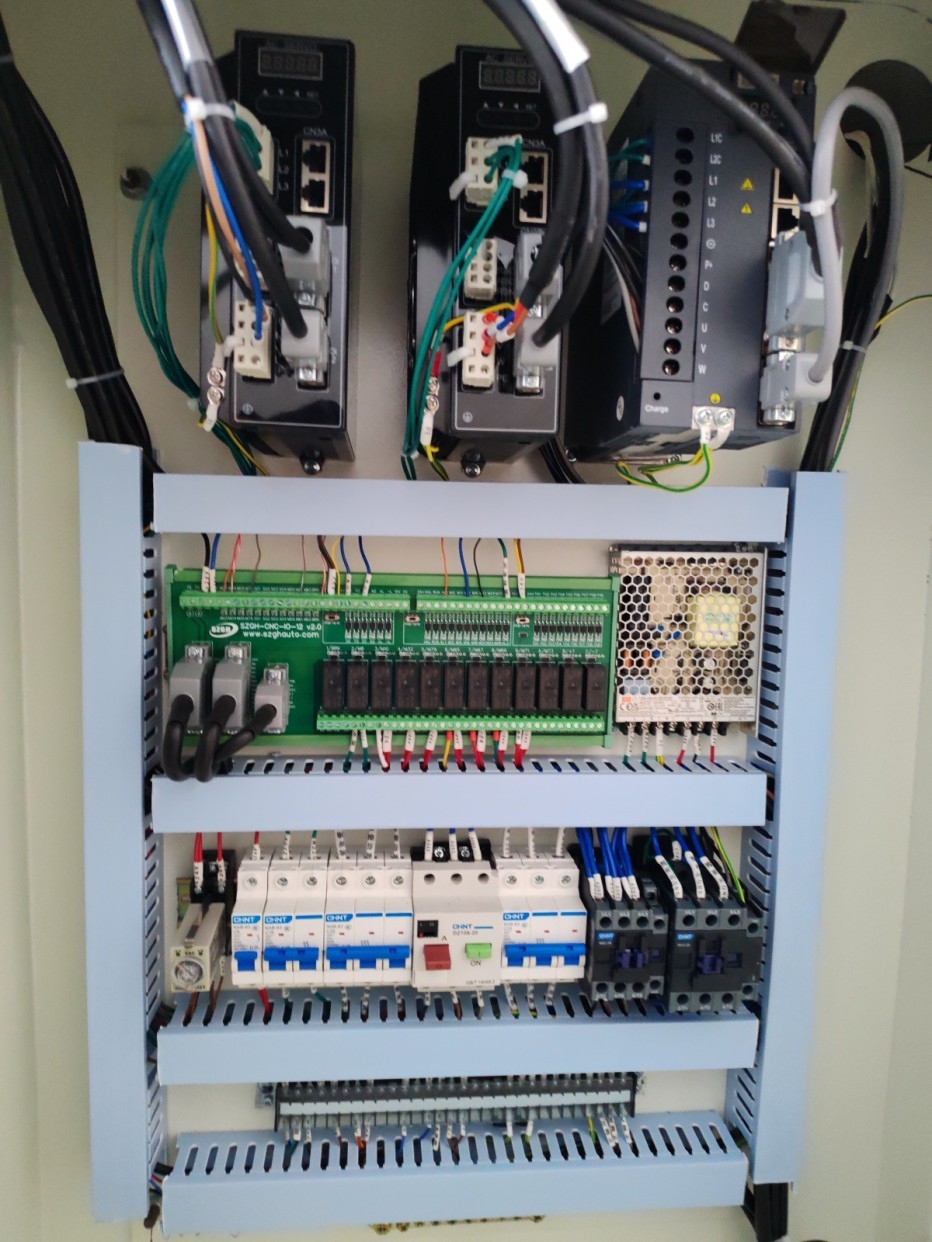

1.The whole lathe machine including the turning system is of independent brand, and the hardware and software are all independently developed, which makes upgrading, learning and operation simple and the service fast;

2.Using Anti-deformation patented heavy-duty base, it is heavy enough to support fast the high-speed and stable movement of the driving head.

3.Using Anti-deformation patented heavy-duty base, it is heavy enough to support fast the high-speed and stable movement of the driving head.

4.The weight is enough to support the anti-vibration and improve the accuracy and smoothness during bar machining.

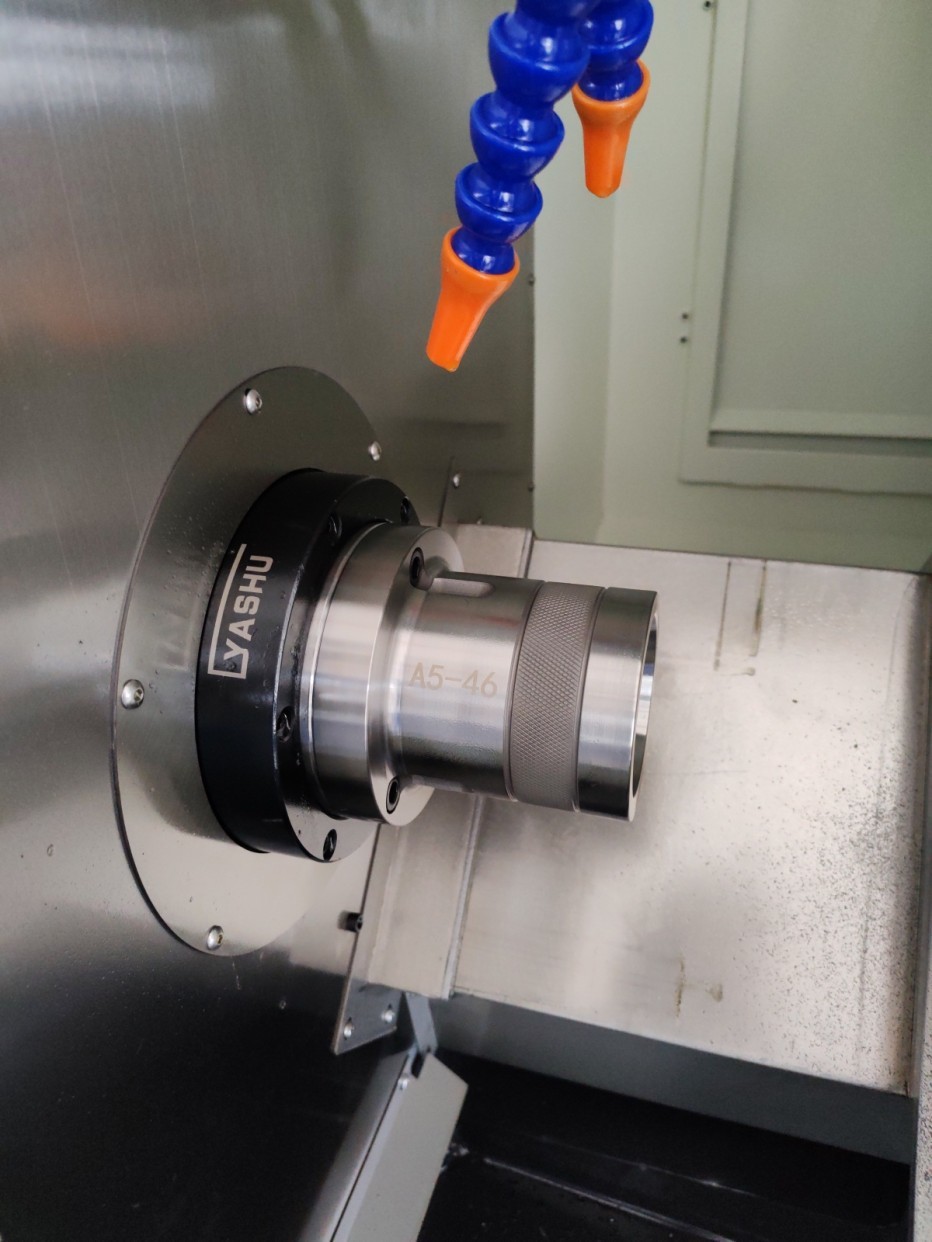

5.The key components adopt high-quality wear-resistant configurations such as Taiwan, and the spindle installation is all

dynamically balanced.

6.Adopting SZGH electric control package to make electromechanical cooperation play the efficiency.

Product Parameter

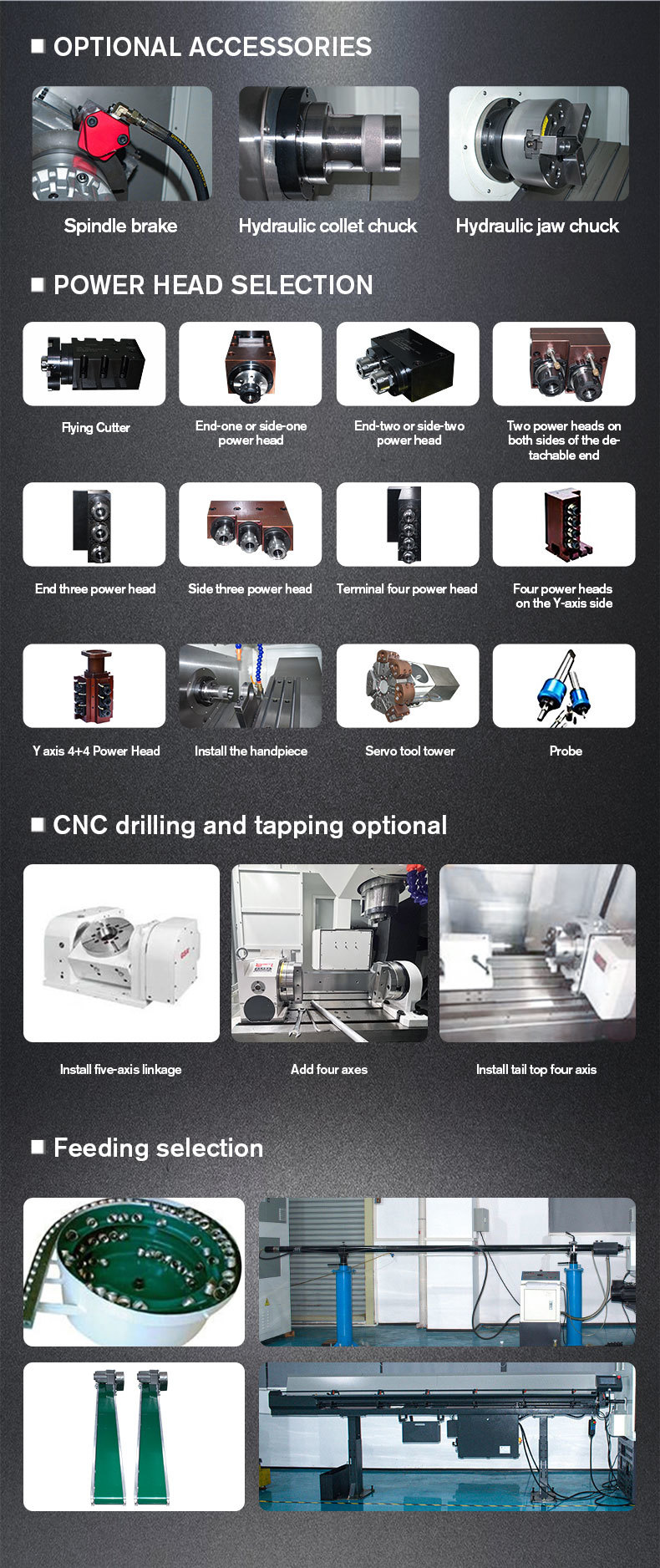

More optional configurations, suitable for processing workpieces of different sizes and complexity.Common optional configurations lathe machinery SZGH-46J are as follows:

Hydraulic chuck,flying cutter, end two or side two power head, end three or side three power head, Four power heads on the Y axis side, Y-axis 4+4 power head, servo turret, oil bath feeder;

When you receive our CNC machines, you will get following service:

1)We have four areas: production area, assembly area, testing area, and finished product area. The machines will be strictly tested and the inspection reports will be sent to customers before they are shipped;

2)The entire machine including the system is of our own brand, and our hardware and software are all independently developed. Upgrading, learning and operation are simple, and the service is fast;

3)We will give you training video and give details information to help you operate step by step;

4)We will build a after-service group in what-app or by-email , and solve your any question or problem ;

5)All of product information such as : display, user manual , software are in English.It is very convenient for your application;

6)24-months warranty time;

7) Free replacement of accessories during the guarantee period if not man-made damage;

8)Online one to one service, so please don’t worry anything. Specially we export to lots of Countries with lots of quantities machines,have rich export experience;

9)Per your demand , we also can arrange local service to you.

CH

CH

INQUIRY

INQUIRY