Products

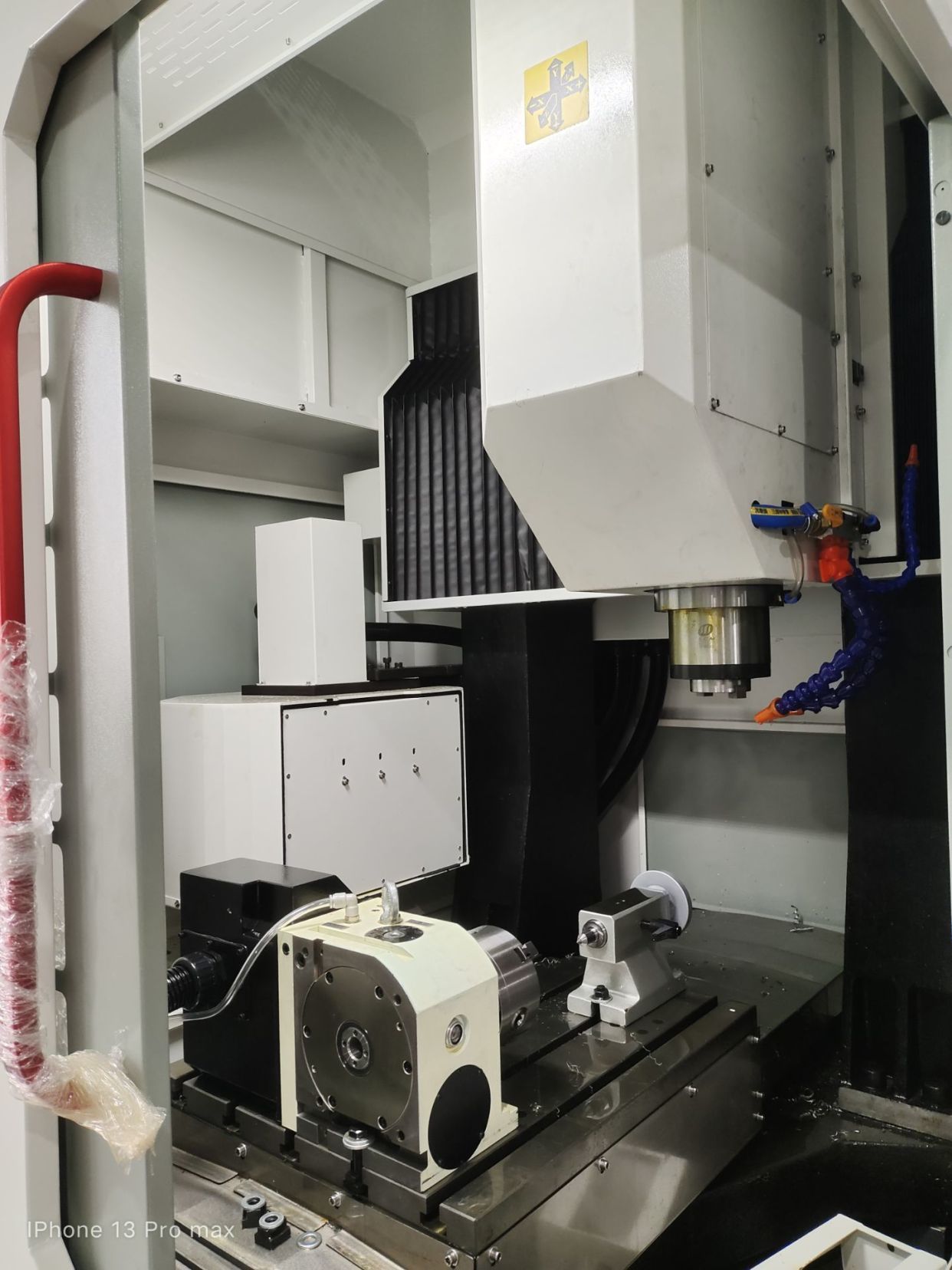

Taiwan Precision P Grade C3 Level Ball Screw CNC Machine Center SZGH-540 With Tool Magazine Capacity 8-station Rigid Tapping Milling Machining Functions

Workbench size (W*L):500*400mm; X/Y/Z axis effective travel:400*500*200mm; Spindle power:3/4.5KW; Tool magazine capacity:8-station tool magazine Tool holder type: BT30 Processing Capacity:milling, boring, drilling and tapping

Classification:

Product Description

Taiwan Precision P Grade C3 Level Ball Screw CNC Machine Center SZGH-540 With Tool Magazine Capacity 8-station Rigid Tapping Milling Machining Functions

Product Overview

Suitable for 8-station processing of copper, iron, aluminum and stainless steel workpiece within 500mm*400mm, and stainless steel parts processing within 8mm tapping and 10mm drilling.

Application Areas

SZGH-540 is an automated CNC milling machine that integrates milling, drilling and tapping functions, and supports automatic tool change ATC function. It is widely used in small and medium batch processing of box parts, small plates, discs, shells, precision parts and other parts in the automotive, mold and other industries.

Products Features

1.Adopting SZGH electric control package to make electromechanical cooperation play the best efficiency.

2.The operation is compatible with the general machining center in the market, and supports drilling, tapping, milling, engraving and other functions.

3.The key components adopt high-quality wear-resistant configurations such as Taiwan, and the spindle installation is all dynamically balanced.

4.Using Anti-deformation patented heavy-duty base, it is heavy enough to support fast the high-speed and stable movement of the driving head.

5.The weight is enough to support the anti-vibration and improve the accuracy and smoothness during bar machining.

6.Due to the small footprint, it is convenient for one person to manage multiple machines, improve per capita output efficiency and reduce processing costs.

Technical Parameter

| Details | SZGH--540A (mechanical spindle) | SZGH-540D (variable frequency electric spindle) | ||

| Workbench | Workbench size (W*L)mm | 500*400 | 500*400 | |

| weight capacity | 200kg | 200kg | ||

| Spindle | Spindle speed | Maximum speed: 6000 rpm | Maximum speed: 24000 rpm | |

| Spindle power | 3kw | 4.5kw | ||

| Spindle taper hole | BT30 | BT30 | ||

| Distance from work table to spindle end face mm | Minimum 150 Maximum 350 | Minimum 150 Maximum 350 | ||

| Feed | Fast-moving | X axis m/min | 25 | 35 |

| Y axis m/min | 25 | 35 | ||

| z-axis m/min | 20 | 25 | ||

| Travels | X-axis effective travel | 400 | 400 | |

| Y-axis effective travel | 500 | 500 | ||

| Z-axis effective travel | 200 (the worktable is 150 from the end face of the spindle) | 200 (the worktable is 150 from the end face of the spindle) | ||

| Processing Capacity | Repeat positioning accuracy mm | 0.01 | 0.01 | |

| Tool magazine capacity | 8-station tool magazine | 8-station tool magazine | ||

| Tool holder type | BT30 | BT30 | ||

| Maximum drilling diameter mm | Aluminum Ф14/ Steel Ф10 | Aluminum Ф18/ Steel Ф14 | ||

| Maximum tapping diameter mm | Aluminum m10/ Steel m8 | Aluminum m12/ Steel m10 | ||

| Maximum milling cutter diameter mm | Ф60 | Ф100 | ||

| Machine tool dimensions length*width*height (mm) | 1350 * 1050 *2050 | 1350 * 1050 *2050 | ||

| Machine weight | 1900 kg | 1900 kg | ||

| The above configuration parameters are used as a reference, and are subject to the listed configuration and physical acceptance of the price. | ||||

Product configuration

| Serial number | product name | manufacturer |

| 1 | controller | SZGH |

| 2 | XYZ three-axis drive, motor | SZGH |

| 3 | Spindle | SZGH |

| 4 | XYZ ball screw | Taiwan precision P grade |

| 5 | guide | Taiwan precision C3 level |

| 6 | Spindle servo motor | SZGH |

| 7 | Tool magazine | SZGH |

Optional configuration

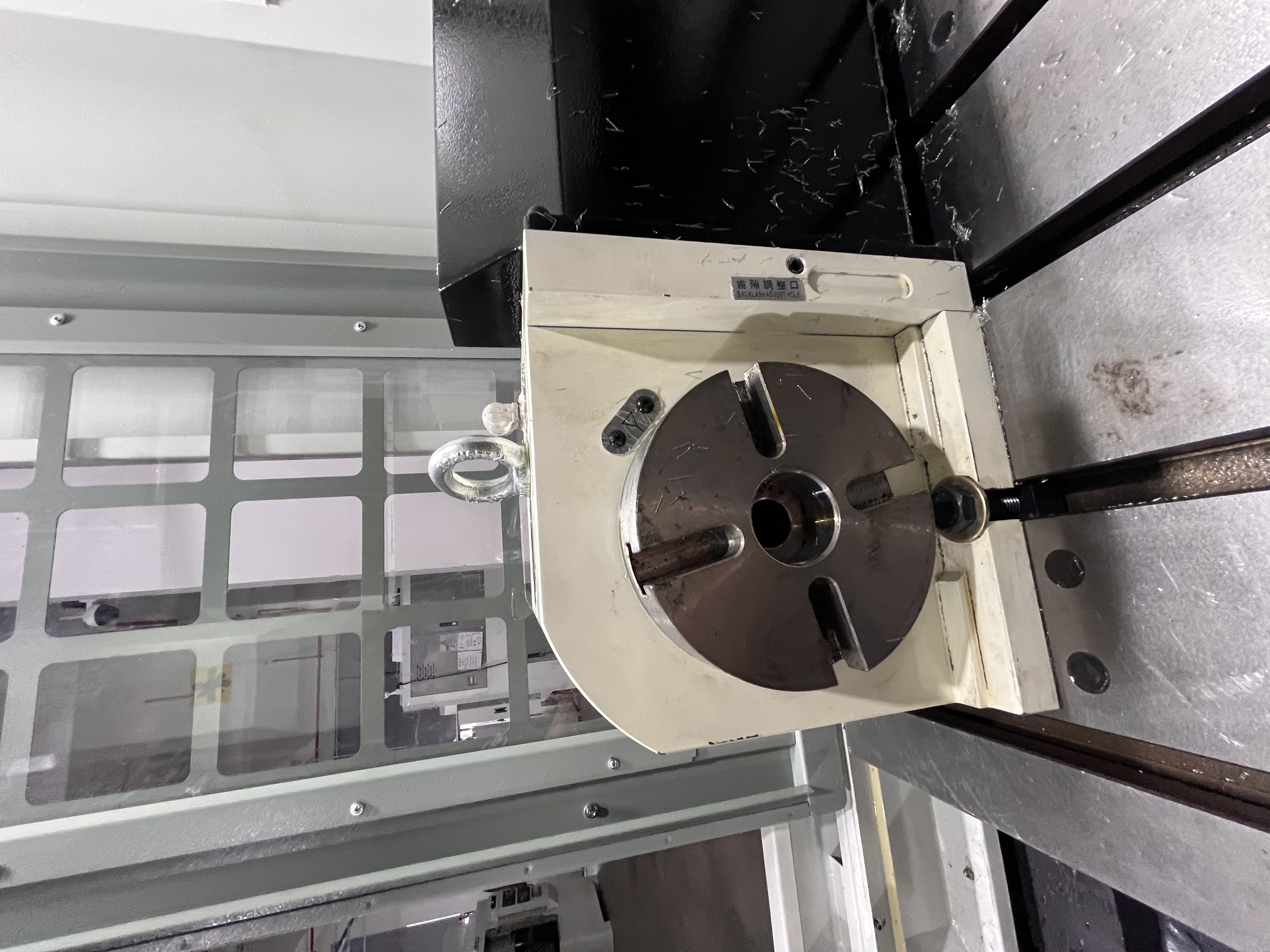

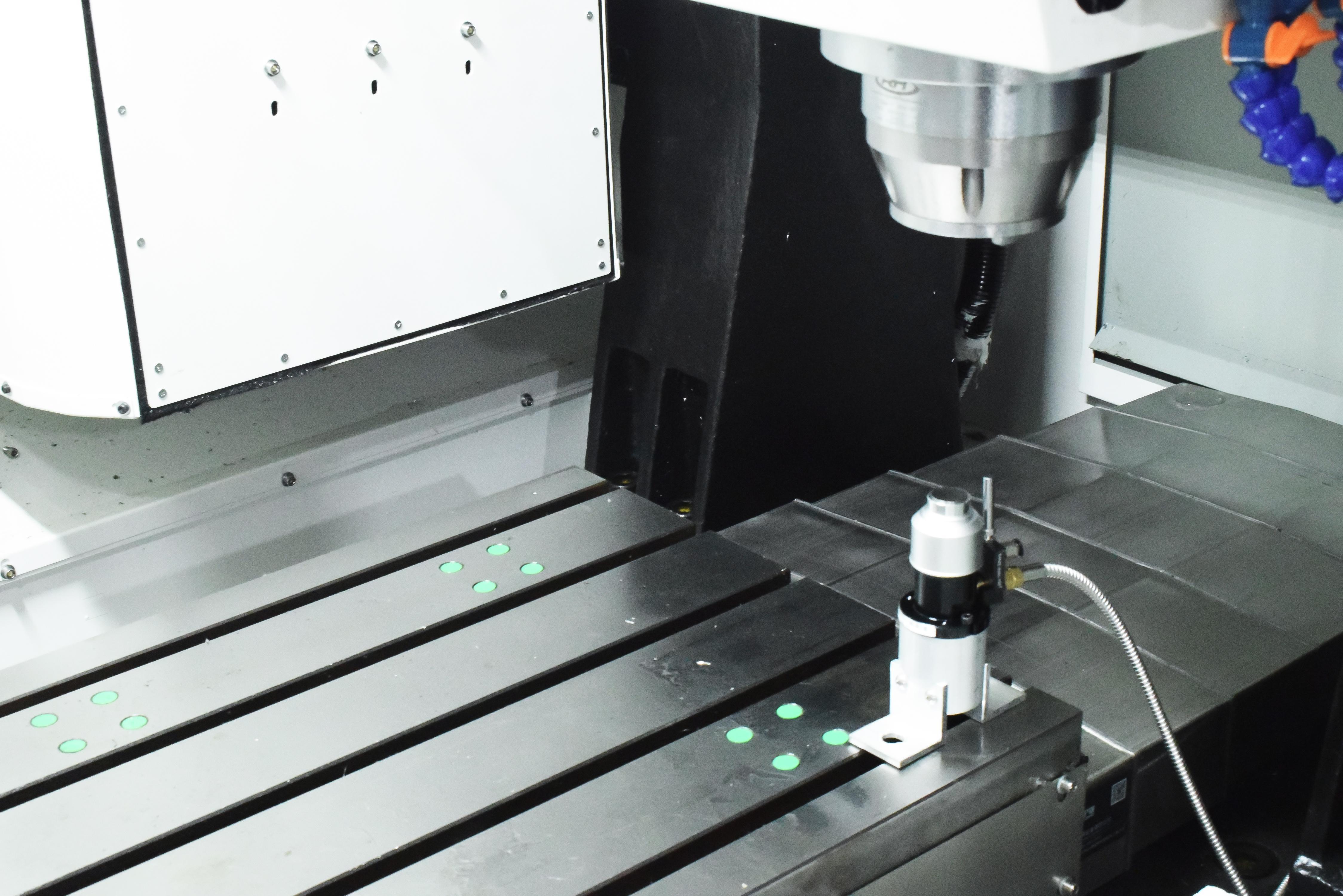

The 4th axis rotary table,tailstock,tool setting probe,probe,etc;

Company Profile

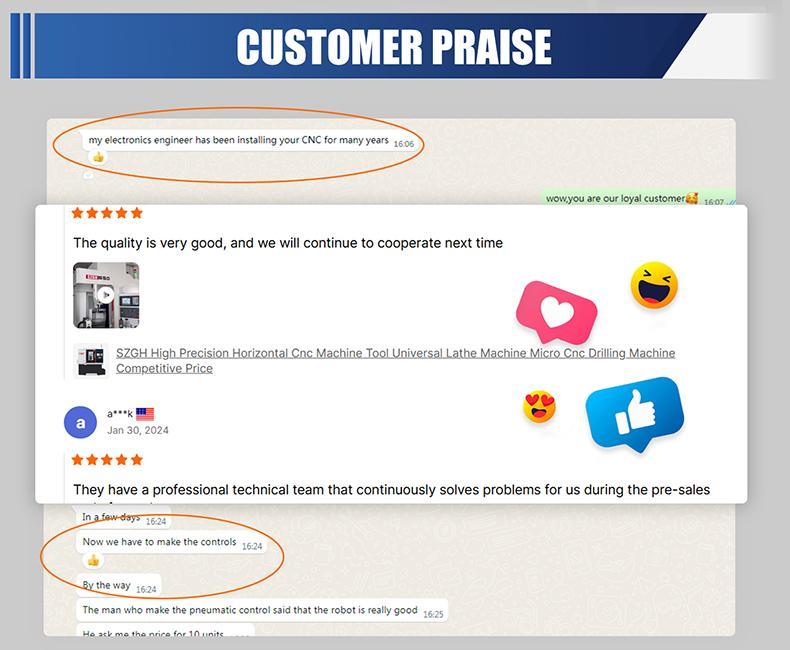

We provide competitive prices with our professional team, strict testing and high quality assurance.Additionally, we offer convenient payment and cost-effective delivery solutions.

SZGH has become an ational high-tech enterprise since 2018 relying on its technical center to provide first-class services and adhering to the concept of "quality is the life of the enterprise".Our success is based on your satisfaction.

Certificates and Honors

Brand Quality&Evaluation

Our Service

When you receive our CNC machines, you will get following service:

1)We have four areas: production area, assembly area, testing area, and finished product area. The machines will be strictly tested and the inspection reports will be sent to customers before they are shipped;

2)The entire machine including the system is of our own brand, and our hardware and software are all independently developed. Upgrading, learning and operation are simple, and the service is fast;

3)We will give you training video and give details information to help you operate step by step;

4)We will build a after-service group in what-app or by-email , and solve your any question or problem ;

5)All of product information such as : display, user manual , software are in English.It is very convenient for your application;

6)24-months warranty time;

7) Free replacement of accessories during the guarantee period if not man-made damage;

8)Online one to one service, so please don’t worry anything. Specially we export to lots of Countries with lots of quantities machines,have rich export experience;

9)Per your demand , we also can arrange local service to you.

Choosing our milling machine processing center is choosing an efficient, accurate and reliable processing solution, which will make your company stand out in the fierce market competition and achieve higher production value and economic benefits. If you are interested in our products or have any questions, please feel free to contact us, we will serve you wholeheartedly!

CH

CH

INQUIRY

INQUIRY