Products

High Rigidity 2 Axis Vertical Lathe Turning Machine Tool Post Drilling and Turning Machining Accuracy ±0.01mm

Economical High-precision Small Vertical Lathe Turning Machine SZGH-36J: Max. diameter of bar bore 35mm; Max. length of workpiece 230mm; X-axis effective travel 600mm; Z-axis effective travel 230mm; Machining accuracy of the workpiece ±0.01mm;

Classification:

Product Description

Product name and model: Small vertical lathe SZGH-36J

SZGH-36J is an economical high-precision small vertical turning machine suitable for efficient disc processing; small footprint, excellent repeat positioning accuracy, easy operation and maintenance.

Max. diameter of bar bore 35mm;Max. length of workpiece 230mm;

X-axis effective travel 600mm;Z-axis effective travel 230mm;

Machining accuracy of the workpiece ±0.01mm;

Technical Parameter

| Project | Unit | Standard value | Max value | |

| Processing capacity | Max. diameter of bar bore | mm | 35 | - |

| Max. particle diameter (disk type) | mm | 250 | 300 | |

| Max. length of workpiece | mm | 210 | 230 | |

| Cutting amount of stainless steel on one side | mm | 2 | 3 | |

| Machining accuracy of the workpiece | mm | ±0.01 | - | |

| Surface roughness | Ra | 1.6 | - | |

| the height of center tool holder | mm | 40 | - | |

| Turning Diameter | mm | 350 | - | |

| Square Knife Specifications | mm | 16 | - | |

| Travels | X-axis effective travel | mm | 600 | - |

| Z-axis effective travel | mm | 230 | - | |

| Feed | X-axis rapid traverse | m/min | 25 | 30 |

| Z-axis rapid traverse | m/min | 25 | 30 | |

| X-axis servo-motor power | kw | 1.3 | - | |

| Z-axis servo-motor power | kw | 1.3 | - | |

| Spindle | Max.Spindle Speed | rpm | 3500 | 4000 |

| Spindle Motor Power | kw | 3 | ||

| Spindle nose taper | - | A2-4 | ||

| Support hydraulic chuck size | inch | 6 | 8 | |

| Dimensions | Dimensions | mm | 1750 x 1400 x 1800 | |

| Total Weight | kg | 1800 | ||

| Machine tool specifications and component items | Specification | Standard | |

| Part Specifications | Screw | 25mm | Ball grinding precision grade |

| Guide rail | 25mm | H-class linear guide rail | |

| Bearing | - | Two-axis Harbin high-speed angular joint fusion bearing | |

| Spindle motor | 3KW | Variable frequency drive type | |

| Feed servo | 1.3KW | SZGH | |

| CNC Control | - | SZGH | |

| Machine specifications | Bed Type | 30° | Slant Bed |

| Base form | - | Heavy-duty anti deformation patented base | |

| Clamping method | - | hydraulic clamping | |

Machine tool structure:

1. Bed Material: adopts anti-deformation patented heavy-duty base, which is heavy enough to support the high-speed and stable movement of the drive head. It is heavy enough to effectively resist shock and improve the accuracy and smoothness of bar processing.

2. Key Components: adopt high-quality wear-resistant configurations such as Taiwan, and the spindle installation is dynamically balanced.

3. SZGH CNC SZGH-880TC control kit: enables the electromechanical coordination to achieve the best efficiency.

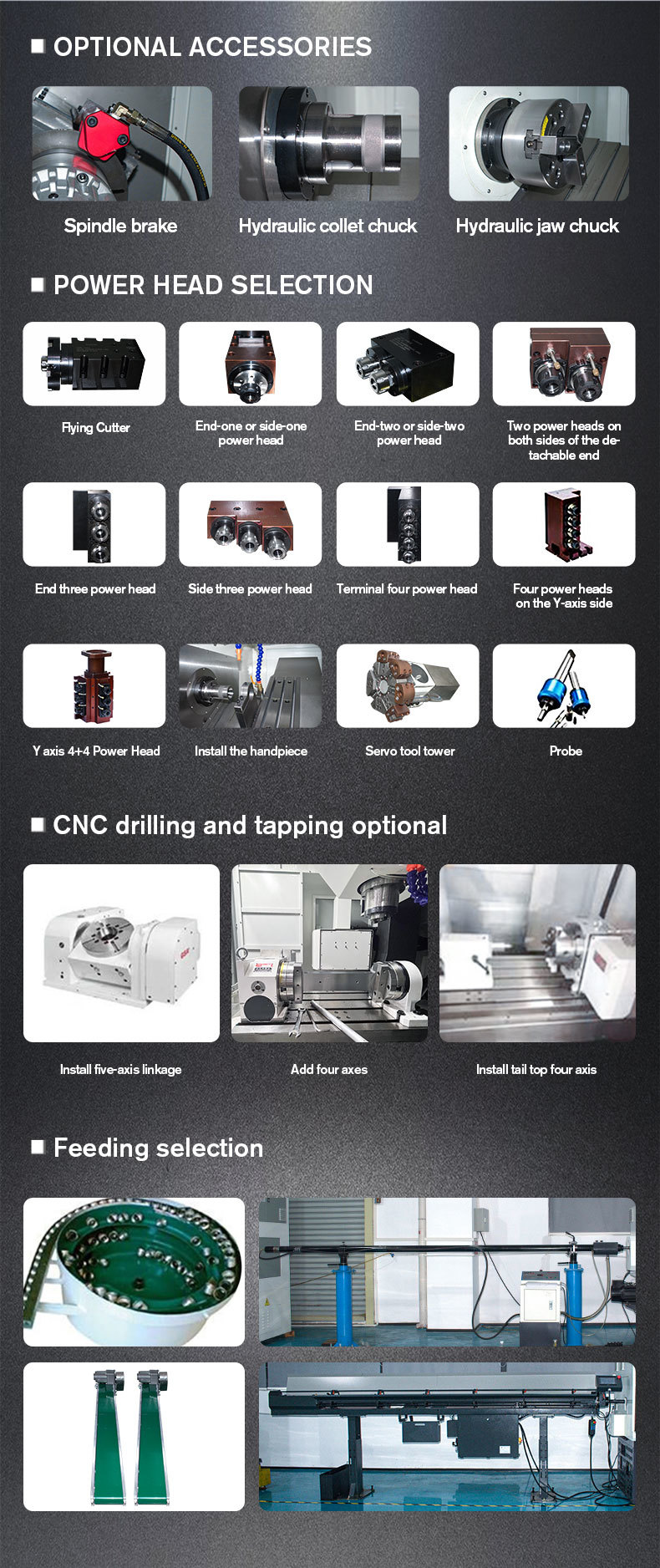

Options & Accessories

Flying cutter (for turning diamond and square shapes)

Hydraulic chuck (for processing short materials)

Nose support (for processing longer materials)

End-one or side-one power head

End-two or side-two power head

Four power heads on Y axis

Oil bath feeding

Fully automatic feeder

Typical processing workpieces and application industries

Applicable to batch production of copper, iron, aluminum, and stainless steel bars within 35mm, and automatic feeding batch production of forged parts and other granular materials within 50mm.

Adopting multiple patented technologies such as high rigidity and anti-deformation structure, it is suitable for processing products with a single-side cutting amount within 2mm, a precision tolerance within ±0.01mm, and a finish of 1.6.

Widely used in the upgrading of hard rail CNC lathes, cam automatic lathes and hydraulic lathes, realizing automated production to save labor costs and improve product quality.

Company Profile

Quality Certification

After-sales service and support

1)We have four areas: production area, assembly area, testing area, and finished product area. The machines will be strictly tested and the inspection reports will be sent to customers before they are shipped;

2)The entire machine including the system is of our own brand, and our hardware and software are all independently developed. Upgrading, learning and operation are simple, and the service is fast;

3)We will give you training video and give details information to help you operate step by step;

4)We will build a after-service group in what-app or by-email , and solve your any question or problem ;

5)All of product information such as : display, user manual , software are in English.It is very convenient for your application;

6)24-months warranty time;

7) Free replacement of accessories during the guarantee period if not man-made damage;

8)Online one to one service, so please don’t worry anything. Specially we export to lots of Countries with lots of quantities machines,have rich export experience;

9)Per your demand , we also can arrange local service to you.

Previous Page

Previous Page

CH

CH

INQUIRY

INQUIRY