Products

High Performance CNC Vertical Lathe Brand New Inclined Bed 2 Axis Turning Center Lathe Working CNC Machine

Product highlights: 30° inclined bed 2 axis small CNC lathe turning machine; X/Z effective travel: 600*230MM; Maximum bar hole diameter: 35MM, maximumlength of workpiece: 210MM; Adopt SZGH-880TC CNC lathe system,achieve the best efficiency of electromechanical synergy; Taiwan 25 ball grinding precision screw; Heavy duty anti-deformation patented machine base,with excellent shock absorption and stability;

Classification:

Product Description

Brand New Inclined Bed 2 Axis Turning Center Lathe Working CNC Machine

SZGH small CNC lathe is a precision processing equipment based on digital control technology, specially used for turning bar and disc parts. Its overall size is smaller than that of large CNC lathe machine tool, and the diameter of the worktable is generally between 230-600mm. It is suitable for high-precision and high-efficiency processing of small and medium-sized parts, and is widely used in machinery manufacturing, electronics, auto parts, instrumentation and other industries.

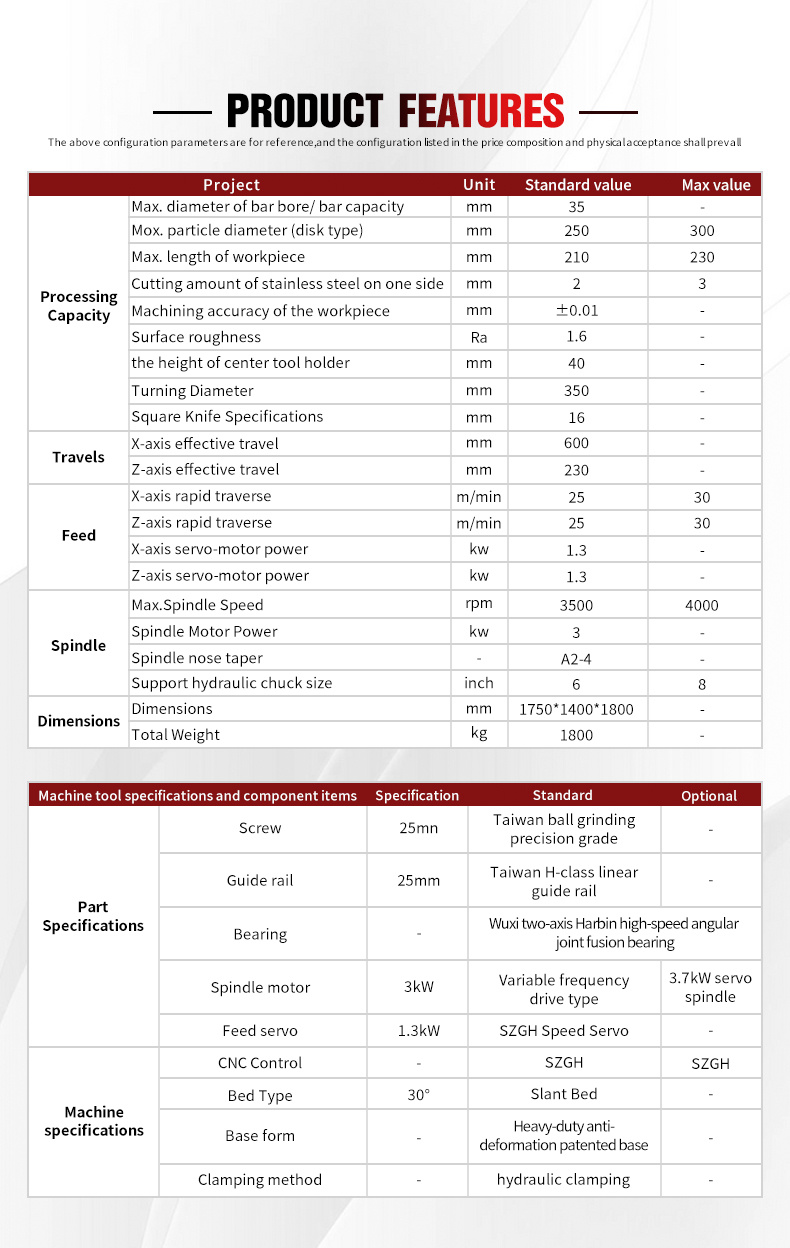

Technical Parameter

It is suitable for batch production of copper, iron, aluminum and stainless steel bars within 35mm, and automatic feeding batch production of forged parts and other granular materials within 50mm. It adopts a number of patented technologies such as high rigidity and anti-deformation structure, and is suitable for processing products with a single-side cutting amount within 2mm, a precision tolerance within ±0.01mm, and a finish of 1.6. It is widely used in the upgrading of hard rail CNC lathes, cam automatic lathes and hydraulic lathes to achieve automated production to save labor costs and improve product quality.

Product Features

This CNC 2-Axis inclined bed lathe series combines proven machine design with advance technology in lathe control and manufacturing. Reliability and stability make these a favorite among demanding job shops and in-house productions alike. Adopt SZGH-880TC CNC system to make the electromechanical synergy play the best efficiency;

CNC System Features

1) 800x600 true color LCD, Chinese、English、Russia language display support;

2) Support grating ruler signal feedback function;

3) Cortex-A8+Fpga platform, main frequency 1GHz, 0.5ms interpolation cycle, 0.1um control accuracy;

4) Linux operating system, USB and micro SD card interface support, realize mass program DNC processing;

5) Yaskawa M-Ⅱ bus protocol, optional EthCAT bus protocol or pulse control;

6) 17-bit, 23-bit absolute encoder support, high precision, no return to zero, full closed-loop control;

7) Open built-in PLC, ladder diagram online editing display, signal diagnosis, signal tracking;

8) Real-time graphic display of machining tool trajectory, full diagnosis, alarm interface, real-time monitoring;

9) Class B macro instruction programming, macro program call with parameters support;

10) Adapting servo spindle can realize continuous positioning, rigid tapping, rigid thread processing;

11) Can turn various threads, thread tail length, thread cutting angle can be set;

Uniformly adopts independent brand systems and machine tools, which are easy to operate;

Optional Accessories

Disk brake device;Hydraulic Chuck:5 inch/6 inch;Flying cutter;

End one or side one power head/end two or side two power head;Four power heads on the Y axis side;

Install the handpiece;Oil bath feeder/Fully automatic feeding;

CH

CH

INQUIRY

INQUIRY