Products

Horizontal lathe SZGH-46J cnc lathe system processing bar material within 45mm

Standard configuration of SZGH-46J(5.5KW) 1.X axis :1000mm,Z axis :400mm; 2.SZGH 130 servo motor 1.5KW, X axis with brake, Z axis without brake; 2. SZGH 2 axis CNC lathe controller; 3. Standard type screw and guide rail, bearing; 4. 5.5KW spindle servo motor ;

Classification:

Product Description

Horizontal lathe SZGH-46J cnc lathe system processing bar material within 45mm

Lathe processing is a type of cutting processing, which is to contact the cutting tool with the rotating material, and process it into the target shape while cutting off the unnecessary parts.

Our lathe Machine SZGH-46J can support four processing methods: outer diameter processing, inner diameter processing, thread cutting processing, and cutting processing.

Standard configuration of SZGH-46J(5.5KW)

1.X axis :1000mm,Z axis :400mm;

2.SZGH 130 servo motor 1.5KW, X axis with brake, Z axis without brake;

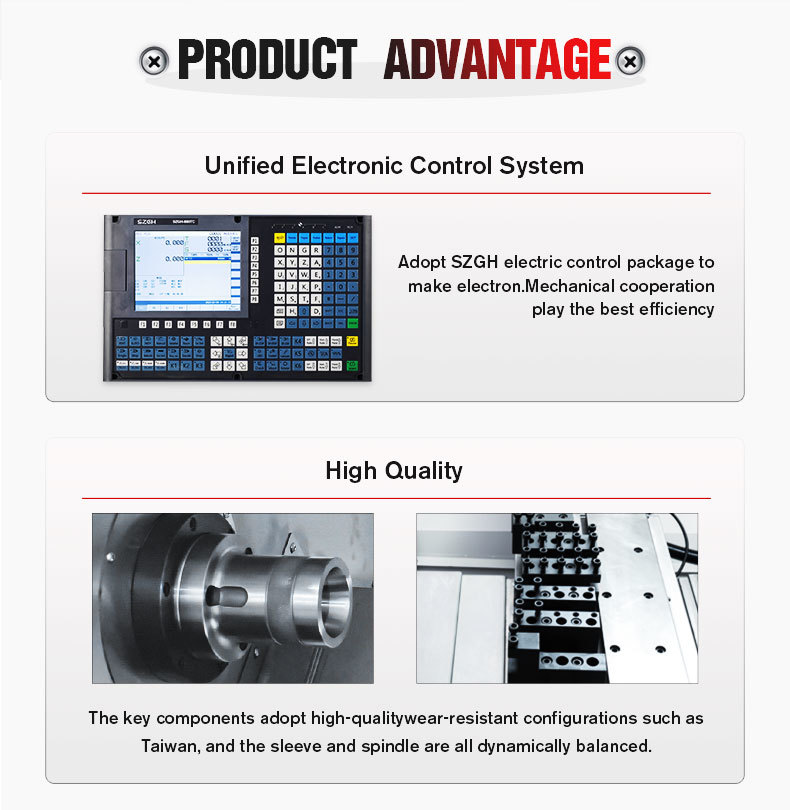

2. SZGH 2 axis CNC lathe controller;

3. Standard type screw and guide rail, bearing;

4. 5.5KW spindle servo motor ;

Product Description

1.It is suitable for batch production of copper, iron, aluminum and stainless steel bars within 45mm, and batch production of open-type forged parts with automatic feeding of pellets within 60mm.

2.It can also be equipped with hydraulic chucks for single-piece production of parts within 350mm. Using multiple patented technologies such as high rigidity and anti-deformation structure, it is suitable for processing products with a single-side cutting amount within 4mm, precision tolerance within ±0.0075mm, and smoothness within 1.6.

3.It is widely used in the processing of large parts with high precision and rigidity. Through careful design and matching, the performance of each accessory can be fully utilized to achieve the cost-effective ratio.

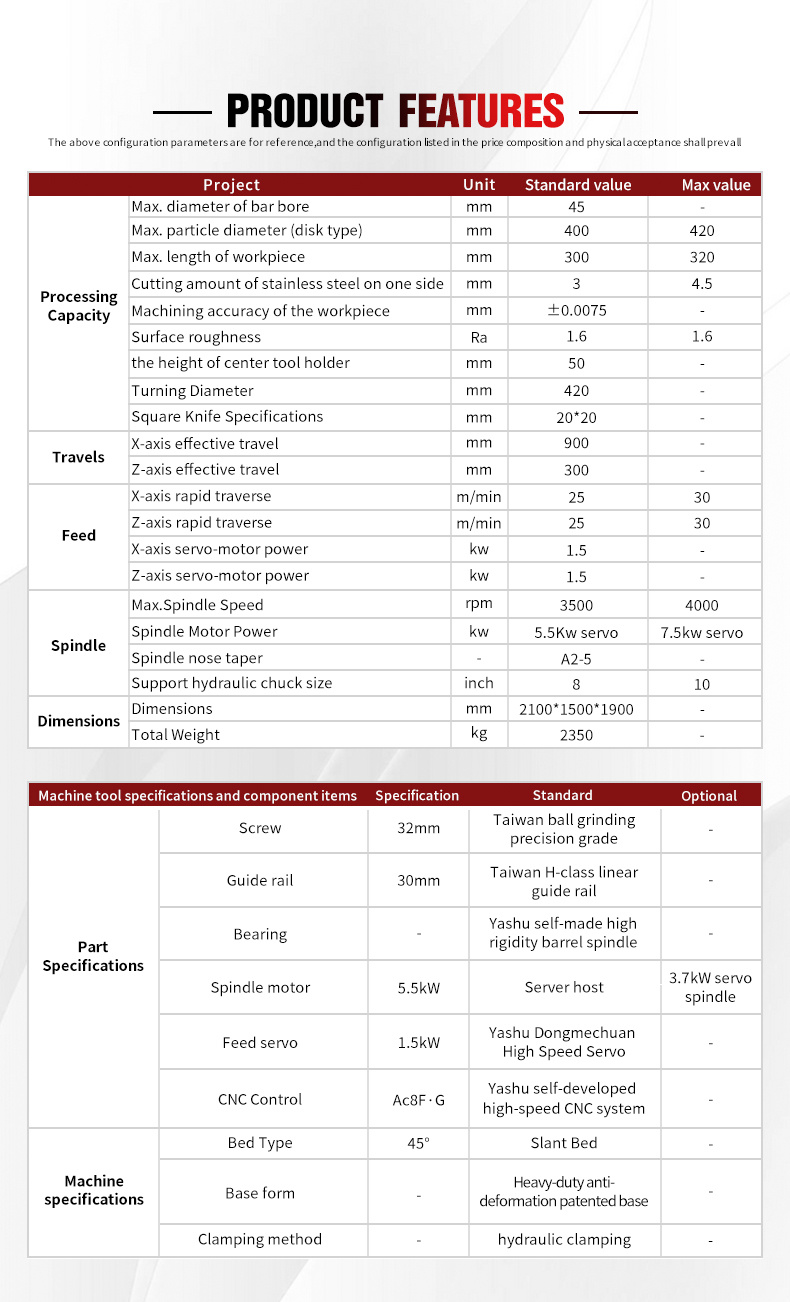

Product Features

1.Using Anti-deformation patented heavy-duty base, it is heavy enough to support fast the high-speed and stable movement of the driving head.

2.The weight is enough to support the anti-vibration and improve the accuracy and smoothness during bar machining.

3.The key components adopt high-quality wear-resistant configurations such as Taiwan, and the spindle installation is all

dynamically balanced.

4.Adopting SZGH electric control package to make electromechanical cooperation play the efficiency.

Product Parameter

Optional Accessories

CH

CH

INQUIRY

INQUIRY