Products

Characteristics and processing methods of SZGH Lathe Machine

SZGH lathe machine: A highly cost-effective lathe machine built with a new design concept; With characteristics of strong anti-interference, stable and reliable operation; With USB interface, equipped with handheld box and additional panel, operation are more flexible; Automatic processing can be achieved by programming the processing conditions and loading them in advance; Since it operates according to the program, even beginners can perform machining with a certain degree of accuracy; Suitable for high-volume products that require repeated work.

Classification:

Product Description

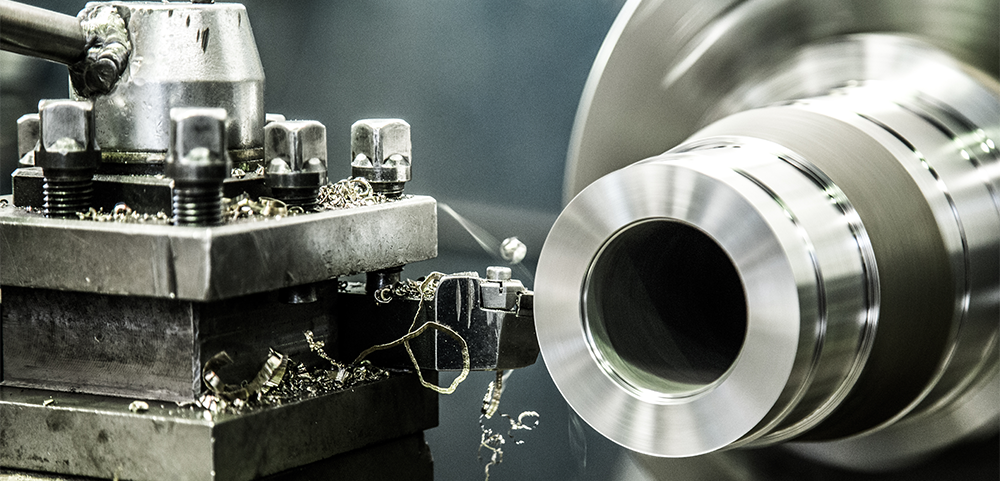

Lathe turning is a processing method that achieves a target shape by cutting materials, and is classified as cutting processing.

Here we will introduce the characteristics and advantages of SZGH Lathe Machine Turning Processing.

1.What is turning processing ?

Turning processing is a type of cutting processing. Cutting processing also includes milling processing and drilling processing, but in turning processing, the cutting tool is brought into contact with the rotating material, and the unnecessary parts are cut off while processing into the target shape.

Turning processing is similar to milling processing, which is also included in cutting processing, but differs in "what is rotated." In turning processing, the material to be processed is rotated, while in milling processing, the material is fixed and the cutting tool is rotated for processing.

2.Basic processing methods of SZGH Lathe Machine:

SZGH Lathe Machines support four basic processing methods: outer diameter processing, inner diameter processing, thread cutting, and cutting. The following explains each processing method:

(1)Outer diameter processing:

Outer diameter processing is a method in which the cutting tool contacts the rotating material from the outside. It is the most commonly used processing method in turning processing. It is used for finishing to beautify the surface and roughly cutting into the target shape in the initial stage of processing.

During outer diameter machining, the chips generated may become entangled in the cutting tool. When particularly high-precision finishing is required, the angle of the cutting tool needs to be adjusted to prevent chips from entangling and deteriorating accuracy.

(2)Inner diameter processing:

Inner diameter processing, the inside of the material is cut to enlarge the hole created in the material by drilling. Used to adjust the size of the hole and beautify the inside surface.

For inside diameter machining, the tool needs to be lengthened according to the depth of the hole to be machined. However, long tools are prone to offset, so care must be taken to reduce accuracy. Additionally, since chips collect inside the hole, they need to be removed frequently.

(3) Thread cutting:

Thread cutting is a processing method that produces thread pitch. In turning processing, both external threads and internal threads can be processed using special thread cutting tools. In the case of milling and machining centers, usually only internal threads can be made, so the ability to also make external threads is a great advantage of turning processing.

The special thread cutting tool is brought into contact with the material to move the tool at a constant speed. In order to make the pitch equal, the "automatic feed function" is often used to keep the speed constant.

(4) Cutting processing:

Cutting is a processing method in which unnecessary parts are cut off by pressing a tool against the material. It's like cutting a cylinder into discs. It requires the use of tools with thin blades and the need to work while checking for vibrations and sounds, so a certain amount of skill is required. In order to perform high-precision machining, some measures need to be taken, such as using flexible blades, using oil when cutting, etc.

3.SZGH Lathe Machines characteristics:

There are various types of processing equipment used in turning processing, depending on the size of the material and the processing method.

Here we’d like to introduce the types and characteristics of the lathe machine we mainly provide.

(Lathe Models:SZGH-25,SZGH-36J,SZGH-46J;Turn-milling Models:SZGH-36Y,SZGH-46Y)

(1)SZGH lathe machine:

A highly cost-effective lathe machine built with a new design concept;

With characteristics of strong anti-interference, stable and reliable operation;

With USB interface, equipped with handheld box and additional panel, operation are more flexible;

Automatic processing can be achieved by programming the processing conditions and loading them in advance;

Since it operates according to the program, even beginners can perform machining with a certain degree of accuracy;

Suitable for high-volume products that require repeated work.

(2)Advantages of SZGH Lathe Machine:

Through turning processing, round products can be produced. In addition, since the material is cut while rotating, the high dimensional accuracy that can be achieved is a major advantage.

The rotation speed and rotation method can be changed at will. In addition, since the type of tool is also matched to the application, complex-shaped products can be manufactured through combined machining methods.

For more information about our lathe machine series, please leave us a message.

We will help choose suitable model for you as your processing.

Next Page

CH

CH

INQUIRY

INQUIRY