Products

CNC Lathe Machines Manufacturer China Turning Machine 2 Axis X Z Axis CNC Lathe Machinery Instead Of Manual Lathe Machine

SZGH-36J is 2 axis lathe controller which is used in hard rail CNC lathes, replaced by 46 large CNC lathes with small parts, etc., to achieve the effect of improving efficiency and cost-benefit ratio. It is suitable for batch production of copper, iron, aluminum and stainless steel bars within 35mm, and batch production of open-type forged parts with automatic feeding of pellets within 50mm.It can also be equipped with hydraulic chucks for single-piece production of parts within 250mm.Using multiple patented technologies such as high rigidity and anti-deformation structure, it is suitable for processing products with a single-side cutting amount within 2mm, precision tolerance within ±0.01mm, and smoothness within 1.6.

Classification:

Product Description

CNC Lathe Machines Manufacturer China Turning Machine 2 Axis X Z Axis CNC Lathe Machinery Instead Of Manual Lathe Machine

CNC lathe is one of the most widely used CNC machine tools.

SZGH-36J is 2 axis lathe controller which is used in hard rail CNC lathes, replaced by 46 large CNC lathes with small parts, etc., to achieve the effect of improving efficiency and cost-benefit ratio.

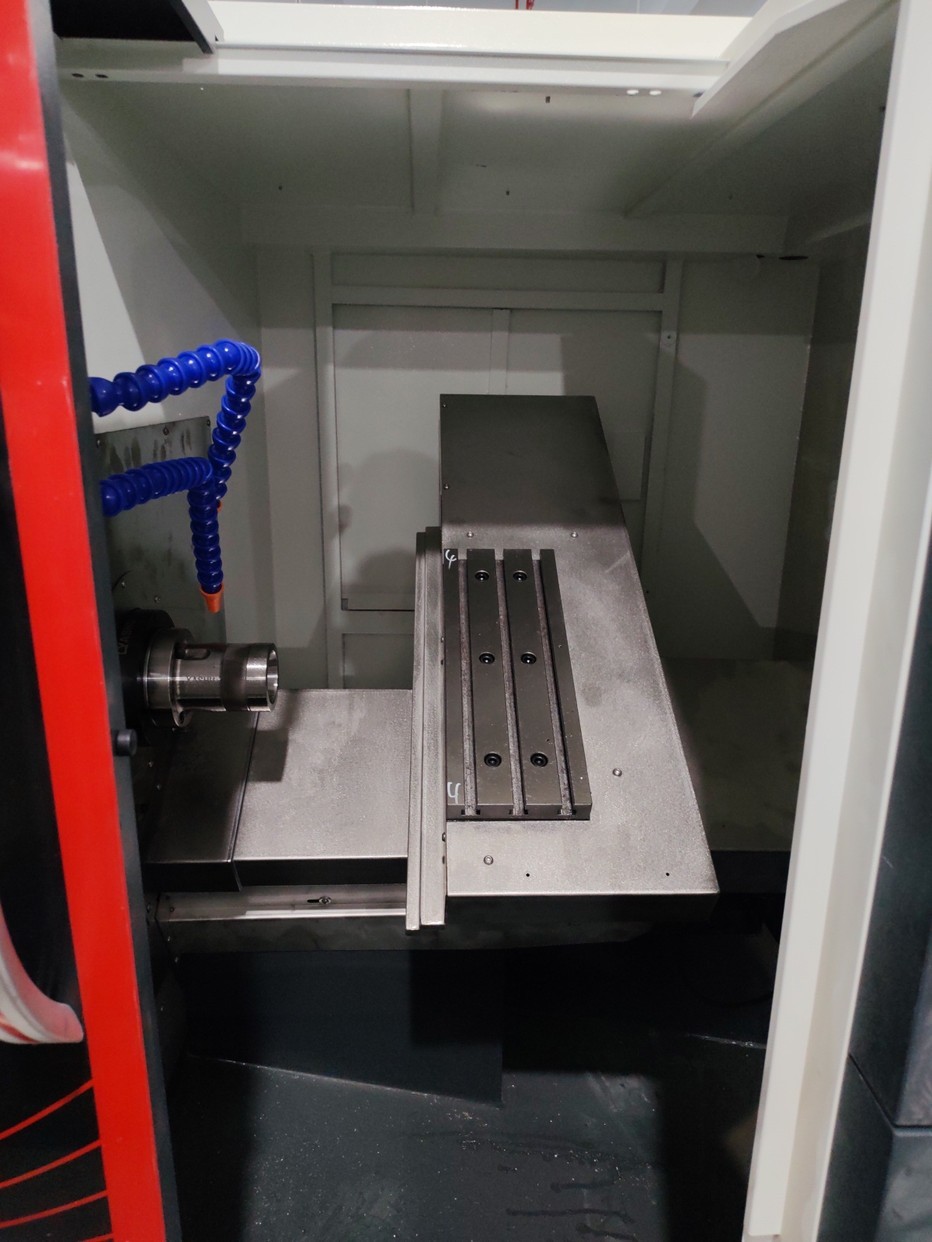

Our lathe machine SZGH-36J is mainly used for cutting inner and outer cylindrical surfaces of shaft parts or disk parts, inner and outer conical surfaces with arbitrary taper angles, complex rotary inner and outer curved surfaces, and cylindrical and conical threads, and can also perform grooving, drilling, reaming, reaming and boring, etc.

Standard configuration of SZGH-36J

1.X axis:600MM;Z axis:230MM;

2.SZGH 110 motor 1.2KW, X axis with brake, Z axis without brake;

3.SZGH 2 axis CNC lathe controller system;

4.Standard type screw and guide rail, bearing;

5.3.7KW spindle servo motor ;

Product Description:

1.It is suitable for batch production of copper, iron, aluminum and stainless steel bars within 35mm, and batch production of open-type forged parts with automatic feeding of pellets within 50mm.

2.It can also be equipped with hydraulic chucks for single-piece production of parts within 250mm.

3.Using multiple patented technologies such as high rigidity and anti-deformation structure, it is suitable for processing products with a single-side cutting amount within 2mm, precision tolerance within ±0.01mm, and smoothness within 1.6.

Product Advantages

SZGH lathe machinery SZGH-36J are equipped with the self-developed cnc lathe controller system SZGH-880TC, which realizes the integration of multiple technologies such as mechanics, electrical, hydraulic, pneumatic, microelectronics and information, ensuring the efficiency of the system and machine tool.

It is equipped with high-quality, high-specification, wear-resistant key components, such as Taiwan guide rails and bearings.

Compared with ordinary machine tools, it has the following characteristics:

High processing accuracy and stable processing quality;

It can be linked with multiple coordinates and can process parts with complex shapes;

When the processed parts are changed, generally only the CNC program needs to be changed, which can save production preparation time;

The machine tool itself has high precision and high rigidity, and can choose favorable processing dosage, with high productivity (generally 3 to 5 times that of ordinary machine tools);

The machine tool has a high degree of automation, which can reduce labor intensity;

Product Features

1.Using Anti-deformation patented heavy-duty base, it is heavy enough to support fast the high-speed and stable movement of the driving head.

2.The weight is enough to support the anti-vibration and improve the accuracy and smoothness during bar machining.

3.The key components adopt high-quality wear-resistant configurations such as Taiwan, and the spindle installation is all dynamically balanced.

4.Adopting SZGH electric control package to make electromechanical cooperation play the efficiency.

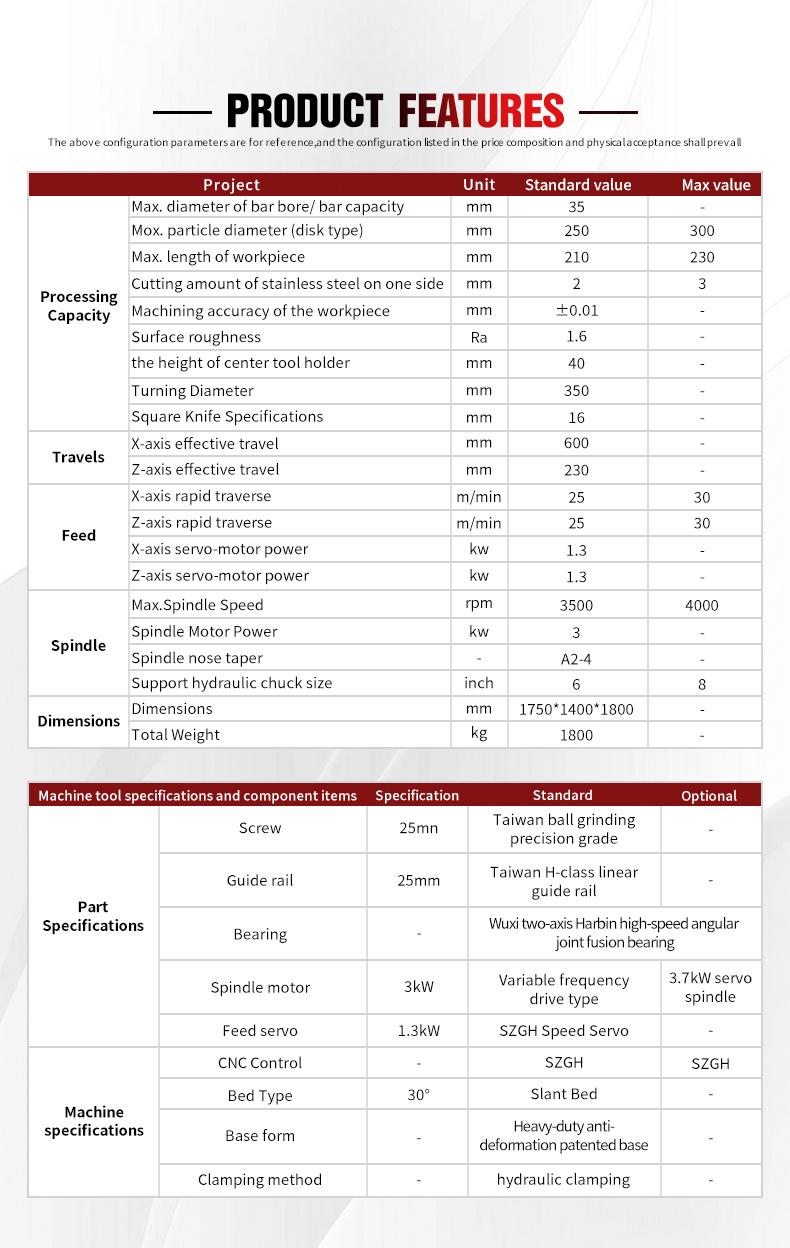

Technical Parameter

Professional System Configuration

SZGH CNC Lathe &Turning Controller System:

1) 2-5 Axis Standard Type and Updated Series CNC Lathe Controller

2) 800x600 8.4 inch real color LCD displayer

3) Electric Turret & Binary code Turret & Special Turret,Max: 99 Pes of tools

4) Support ATC , Macro function and PLC function

5) Support C-axis positioning,rigid tapping,threading of spindle

6) 128MB Memory,100Mb user store room

7) With USB interface,for upgrade & copy programs

8) Analog voltage output of 0~10V in two channels,support double spindles

9) Support Position Feedback with linear scale(Differential signal/RS422)

10) cutter offset:C

11) English menu,program and interface,full screen edition

12) Support macro variable dialog box & Running program by input points

Optional Accessories

Support customization: according to the actual situation of customers such as process requirements, part size, processing range, precision requirements, etc.

Next Page

CH

CH

INQUIRY

INQUIRY