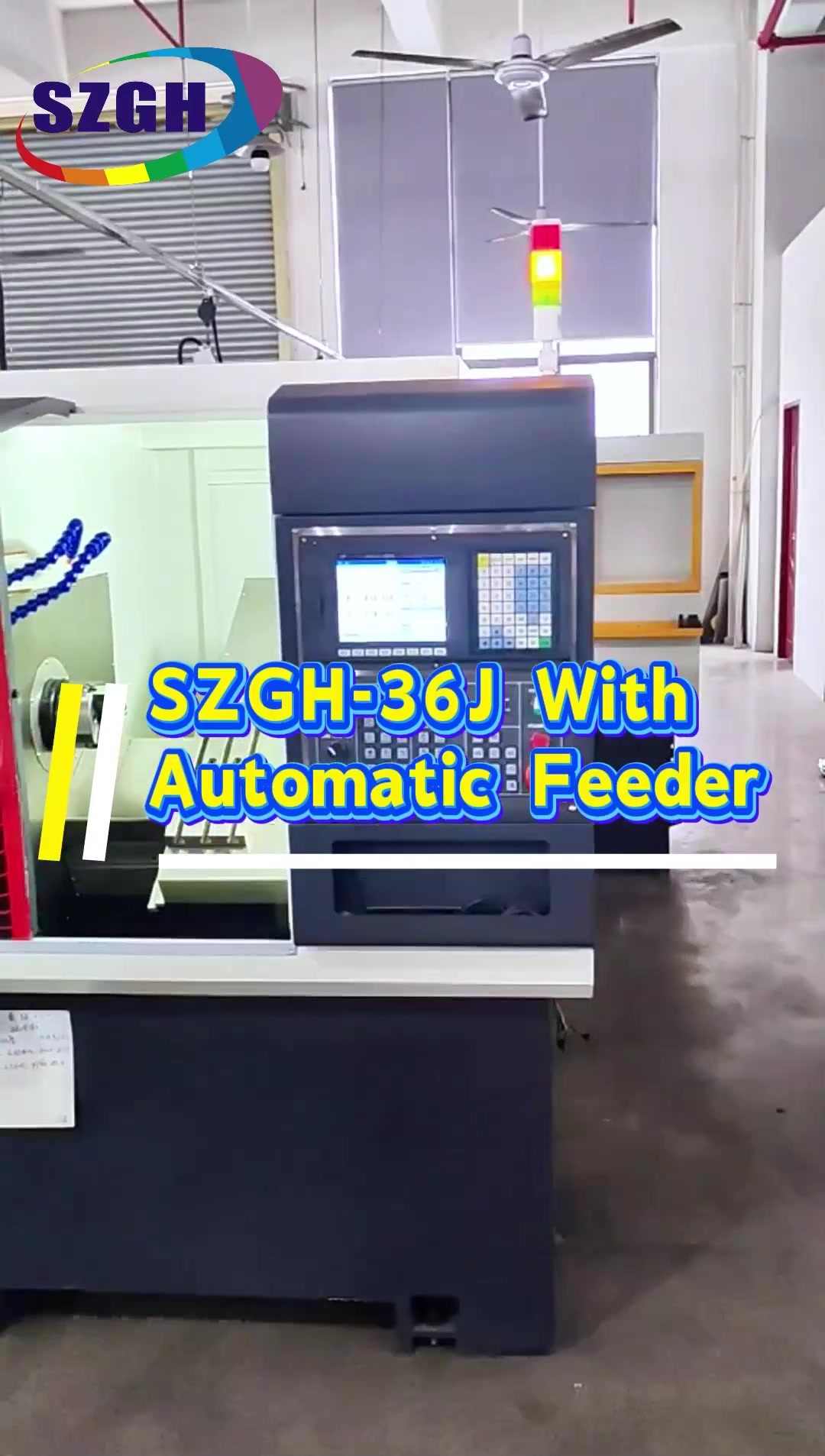

Auto cnc lathe machine SZGH-36J automatic feeding turning and parts loading

2025-06-04

cnc machine,cnc lathe,cnc lathe machine,lathe,mechanical processing,automation ,processing ,automatic feeding,hydraulic chuck ,SZGH-36J,mini lathe cnc,cnc wood lathe machine,cnc machining lathe parts,auto lathe machine,brake lathe machine

As a key equipment in the field of mechanical processing, the lathe machine's degree of automation and processing accuracy have a vital impact on production efficiency and product quality. The lathe's automatic feeding system and hydraulic chuck are important devices to improve lathe performance.

Our lathe SZGH-36J with option automatic feeder and the hydraulic chuck can acheive automatically feed and save your processing time; it realizes automatic feeding and loading. Here takes our customized lathe as an example to introduce more functions of automatic feeding and hydraulic chucks.

Automatic feeding system

Function:

- Improve production efficiency

Realize automatic loading, positioning and transportation of workpieces, reduce manual intervention, shorten loading and unloading time, especially suitable for large-scale, repetitive processing scenarios. - Improve processing accuracy

Through precise mechanical structure and control system, ensure the consistency of workpiece feeding position and avoid positioning errors caused by manual operation. - Reduce labor intensity

Replace manual labor to complete monotonous and frequent loading and unloading work, reduce the physical consumption of operators, and reduce the risk of work-related injuries. - Adapt to complex processing needs

It can be linked with the CNC system to support flexible production of multiple varieties and small batches of workpieces, and quickly switch processing processes.

Hydraulic chuck

Function:

- Clamping the workpiece

Use the hydraulic driving force to fix the workpiece on the spindle to ensure that the workpiece does not move or vibrate during processing, and ensure the processing accuracy. - Quick clamping

The hydraulic system has a fast response speed, which can realize the rapid clamping and loosening of the workpiece, shorten the auxiliary time, and improve production efficiency. - The clamping force is stable and adjustable

By adjusting the pressure of the hydraulic system, the clamping force can be accurately controlled, which is suitable for workpieces of different materials and shapes (such as thin-walled parts, high-precision parts), and avoid deformation of the workpiece due to excessive clamping force. - Automation integration

It can be linked with the CNC system to realize the automatic control of clamping/loosening action, and is suitable for fully automatic lathes or machining centers.

Follow us

Fax:+86-755-61885186

what app&We chat ID: +86-19928711953

Address: Floor 2, Building 5, Southern Digital Innovation Industry Base, No.80 Puxia Road, Henggang Liuyu Community, Longgang District, Shenzhen

SAF Coolest v1.3.1.2 设置面板 GQWSD-ZIXF-XAAEE-AZS

无数据提示

Sorry, the current column is being updated, please look forward to it!

You can view other columns or returnHome Page

CH

CH

INQUIRY

INQUIRY