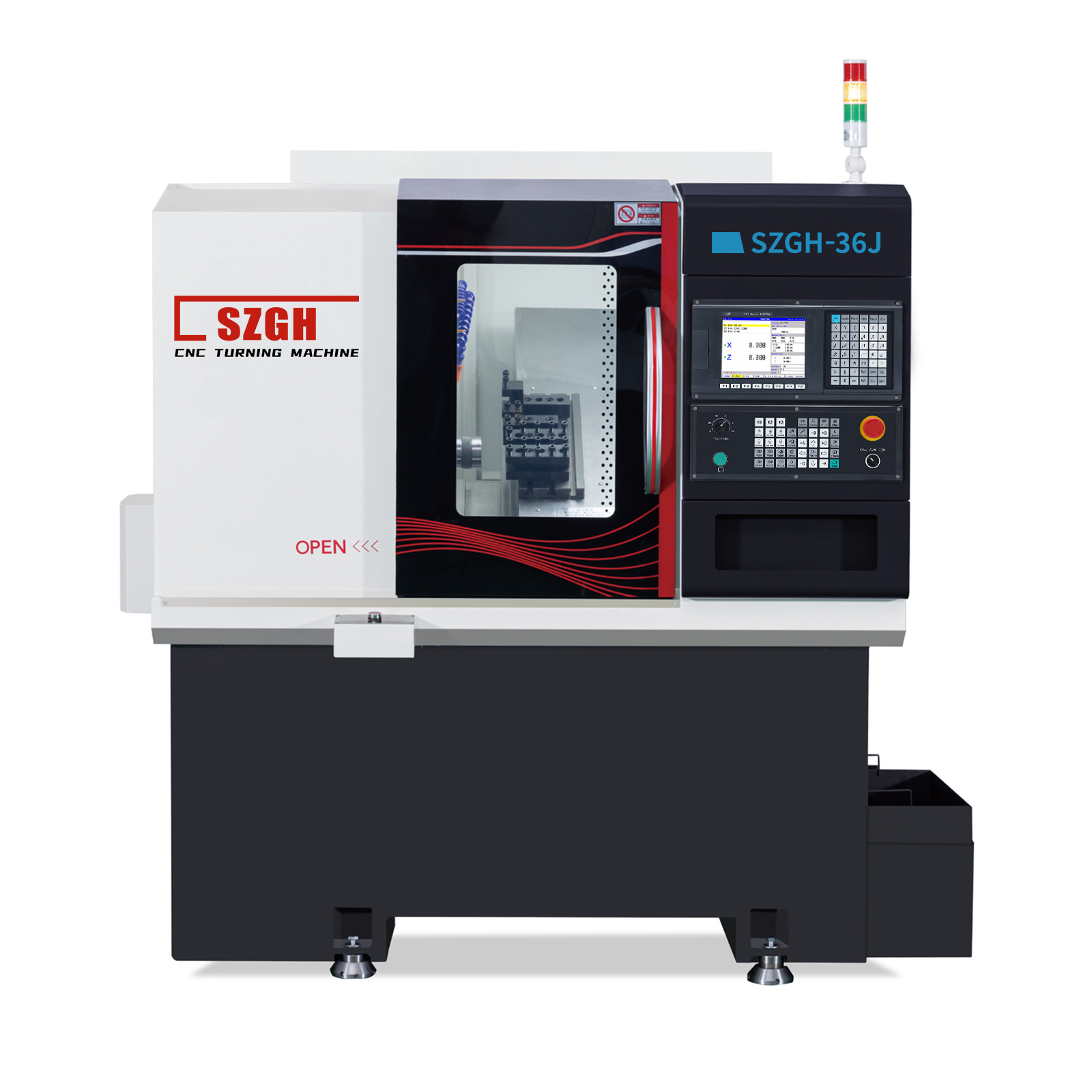

TK50 lathe suitable for processing products in machinery,automobiles,motorcycles

The TK50 series is a simple CNC lathe machine driven by a servo main motor. It has an independent spindle and can realize infinitely variable speed. Equipped with the SZGH-CNC1000TDb/c system, it realizes two-axis control and can automatically complete the processing of internal and external cylindrical surfaces, arbitrary conical surfaces, arc surfaces, end surfaces, and metric and imperial threads, etc.

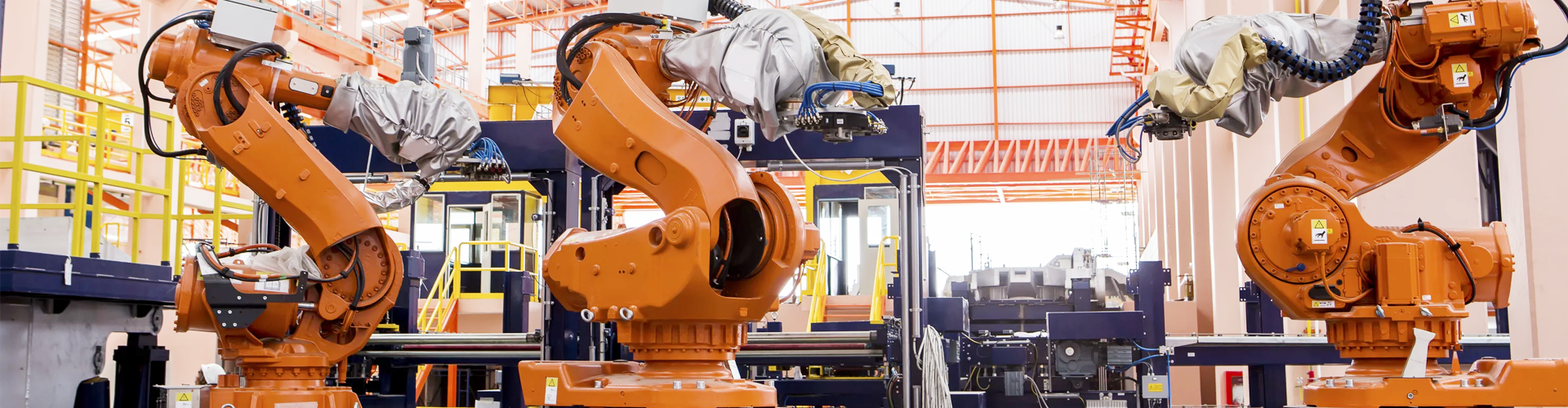

SZGH robot arm work with 40 T Single arm punching machine

Are you still looking for an automated production solution for your single arm punching machine ? Our robots can completely replace manual labor to complete the automatic stamping production of single punching equipment, greatly improving your production efficiency and production safety, and liberating productivity!! Here are the solutions we provide to our customer's production line: Processed products:0.8mm Thick board SZGH provide the solution 1. 8 set SZGH-T1500-C-6 10kg ,6 axis , 1500mm reaching robot arm 2. 8 set Fixture

Lathe machine processing "working with" robots

The case in the video is to install a double-head fixture on our general-purpose SZGH-T series robot, clamp the cutting workpiece and load it into the lathe machine collet to complete the processing. It is more accurate, fast and safer than manually placing materials. For the processing of small and medium-sized parts with large production batches and short processing time, or bulky workpieces that need to be hoisted, the integration of robots and cnc machines is more advantageous.

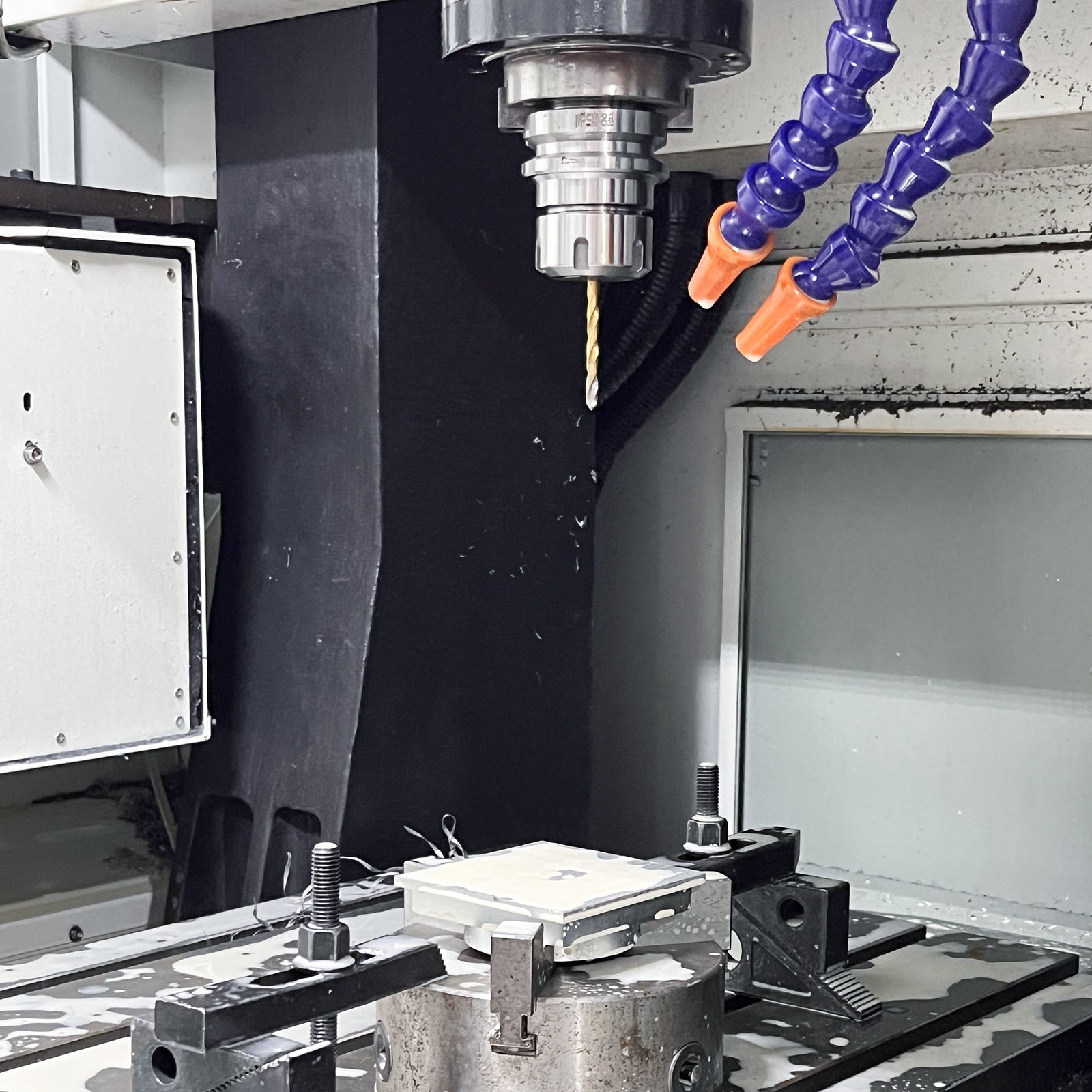

What does a CNC lathe machine do? What are the steps for lathe machine to process parts?

The following are some common application areas of our SZGH lathes machines: 1.Parts processing: It can be used to process various parts, such as mechanical parts, automotive parts, aerospace parts, etc. By writing different processing programs, complex shapes of parts can be processed and processing accuracy and efficiency can be improved. 2.Thread processing: It can be used to process various types of threads, such as internal threads, external threads, special threads, etc. By writing thread processing programs, high-precision and high-efficiency thread processing can be achieved. 3.Milling processing: Milling can be performed using special tools and cutting methods. By writing milling processing programs, complex shapes of milling can be achieved, such as grooving, cutting, contour processing, etc. 4.Hole processing: It can be used to process various types of holes, such as diameter holes, blind holes, inclined holes, etc. By writing hole processing programs, high-precision and high-efficiency hole processing can be achieved. 5.Surface processing: It can be used to process various types of surfaces, such as spheres, cylinders, inclined surfaces, etc. By writing surface processing programs, high-precision and high-efficiency surface processing can be achieved.

What is a welding robot? What are its characteristics?

The characteristics of SZGH welding robots are as follows: 1. Improve welding efficiency. 2. Stabilize welding quality. 3. Help enterprises arrange production. 4. Help enterprises relieve the pressure of recruiting workers.

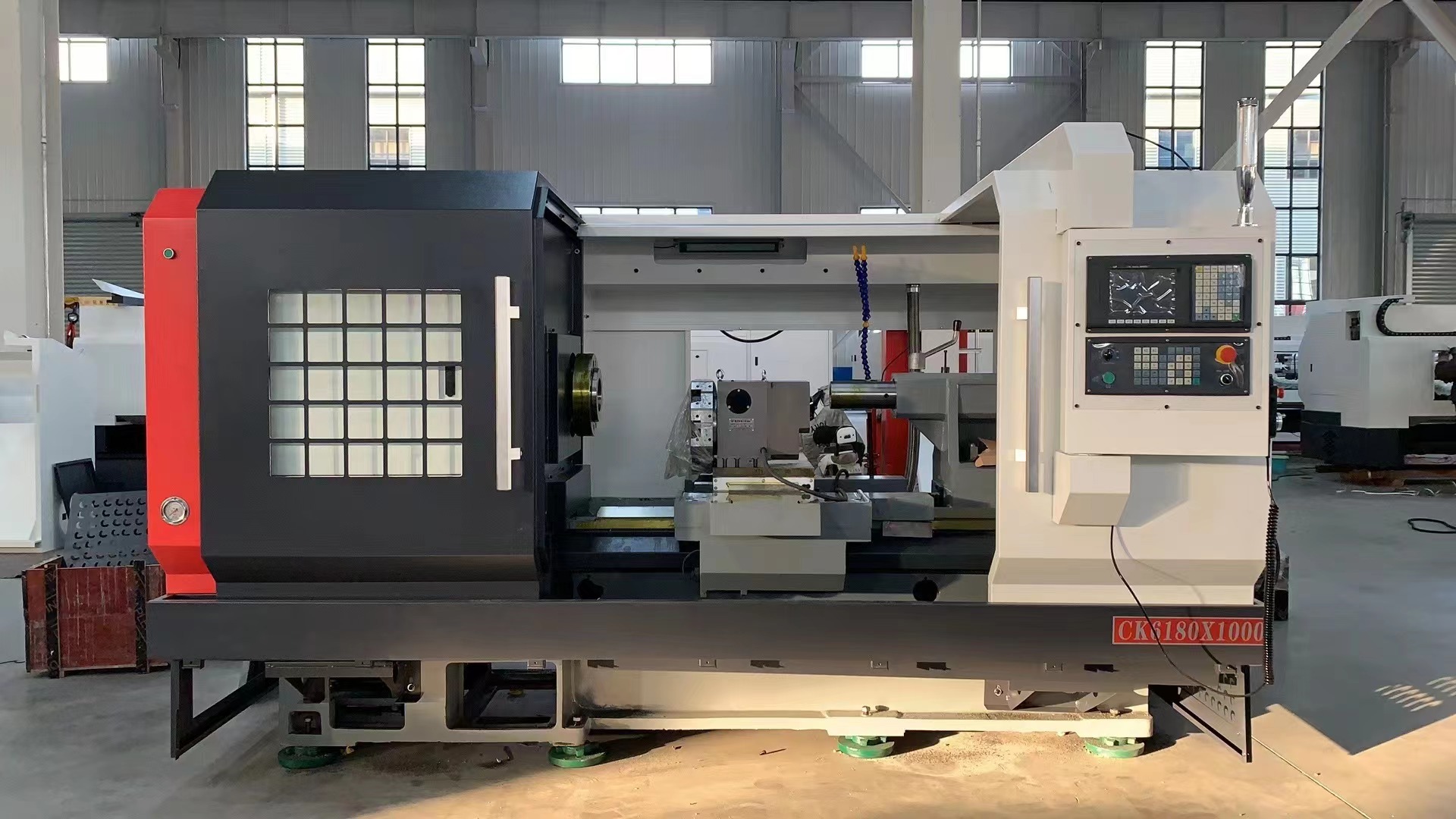

Large lathe machine for multi-variety, small batch mental production

CNC Lathe Machine CK6180 Series 1)3800*1700*1750mm 2)SZGH 130 Servo Motor Driver 3.8KW,15NM; 3)ZGH 2 Axis CNC Absolute Lathe Controller; 4)11KW Spindle Servo Motor ; 5)8 Station Electric Turret; 6)400MM 3 Jaw Manual Chuck;

Characteristics and processing methods of SZGH Lathe Machine

SZGH lathe machine: A highly cost-effective lathe machine built with a new design concept; With characteristics of strong anti-interference, stable and reliable operation; With USB interface, equipped with handheld box and additional panel, operation are more flexible; Automatic processing can be achieved by programming the processing conditions and loading them in advance; Since it operates according to the program, even beginners can perform machining with a certain degree of accuracy; Suitable for high-volume products that require repeated work.

What is the difference between CNC milling machines and machining centers?

Our new series SZGH-650/ SZGH-850 can not only install the milling controller center SZGH-1000MDcb control system, but also the absolute type SZGH-1000MDi control system to achieve five-axis linkage in model SZGH-850. It can also generate digital signals to drive the milling machine mechanism to perform precision machining.

The SZGH collaborative robot has a repeatability positioning accuracy of up to ±0.02 mm. In precision machining, it can ensure the consistency of multiple robots operating simultaneously, realize standardized production of products, improve production quality, and achieve a yield rate of more than 99%. The maximum cycle speed of 4 m/s can efficiently transport parts and improve production efficiency by 20% - 40% during loading and unloading of machine tools

CH

CH

INQUIRY

INQUIRY